MTS MessTechnik Sauerland GmbH offers weighing and dosing systems for bulk materials of all kinds. With its know-how, the company from Germany develops and realizes standard and customer-specific solutions for industrial applications. The products are adapted to the requirements of the application and the customer. “We do it right.“ – with this slogan MTS has developed and manufactures its own weighing systems since 2003: built-in belt scale series (ESW 2.2, EBW 10, EBW 20), the impact scale ImpactWeigh, the dosing scales of DosWeigh series and DiffWeigh as well as the conveyor discharge weigher CDW. All these are manufactured in Germany.

Comprehensive service features from consulting, installation and start-ups to maintenance and support for calibration complete the company profile. MTS is certified to ISO 9001:2015.

MTS customers are from a variety of industries, e.g. wood-processing companies, foundries, recycling industry, pit and quarry industry as well as plant construction.

Categories

Dosing, Measuring, Weighing - Weighing, weighers -

Belt scalesDosing, Measuring, Weighing - Gravimetric feeding -

Flow through dosingDosing, Measuring, Weighing - Gravimetric feeding -

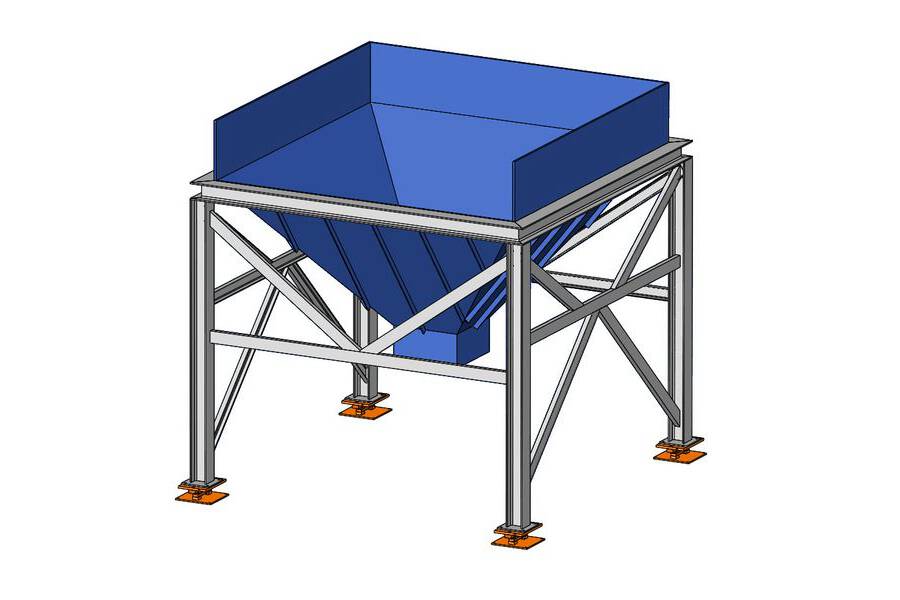

Loss-in-weight feeders (LIW / LWF)Dosing, Measuring, Weighing - Weighing, weighers -

Platform scalesDosing, Measuring, Weighing - Weighing, weighers -

Silo weighers

Show more

Categories

Dosing, Measuring, Weighing - Weighing, weighers -

Belt scalesDosing, Measuring, Weighing - Gravimetric feeding -

Flow through dosingDosing, Measuring, Weighing - Gravimetric feeding -

Loss-in-weight feeders (LIW / LWF)Dosing, Measuring, Weighing - Weighing, weighers -

Platform scalesDosing, Measuring, Weighing - Weighing, weighers -

Silo weighersDosing, Measuring, Weighing - Weighing, weighers -

Vessel weighers