THE MB REVOLUTION REACHES THE FOURTH GENERATION

MB CRUSHER presents the BF90.3 S4 Crusher Bucket to the construction and recycling market. Amazing the market with new ideas and high-performance products is most certainly synonymous with capacity and professionalism. Managing to do so for more than 15 years, not simply amplifying but renewing and strengthening its range, is only one of the reasons why MB CRUSHER is the market leader for crushing and recycling.

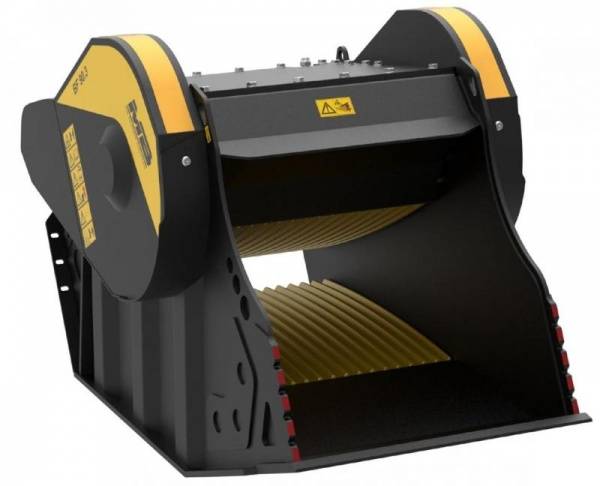

BF90.3 S4

Produced and patented, the BF90.3 was the first crusher bucket in the world ever made.

Designed to resist the most challenging conditions on any site, the BF90.3 - extremely compact and versatile - has been updated and made more powerful over the years. Suitable for all crushing operations, even the most challenging, it maintains the same results in terms of performance with all types of inert material.

In particular, exactly one year on from the last update, this model has been optimised to allow:

•An increase in productivity, thanks to a functional restyling of the internal structure of the machine which allows for an increase