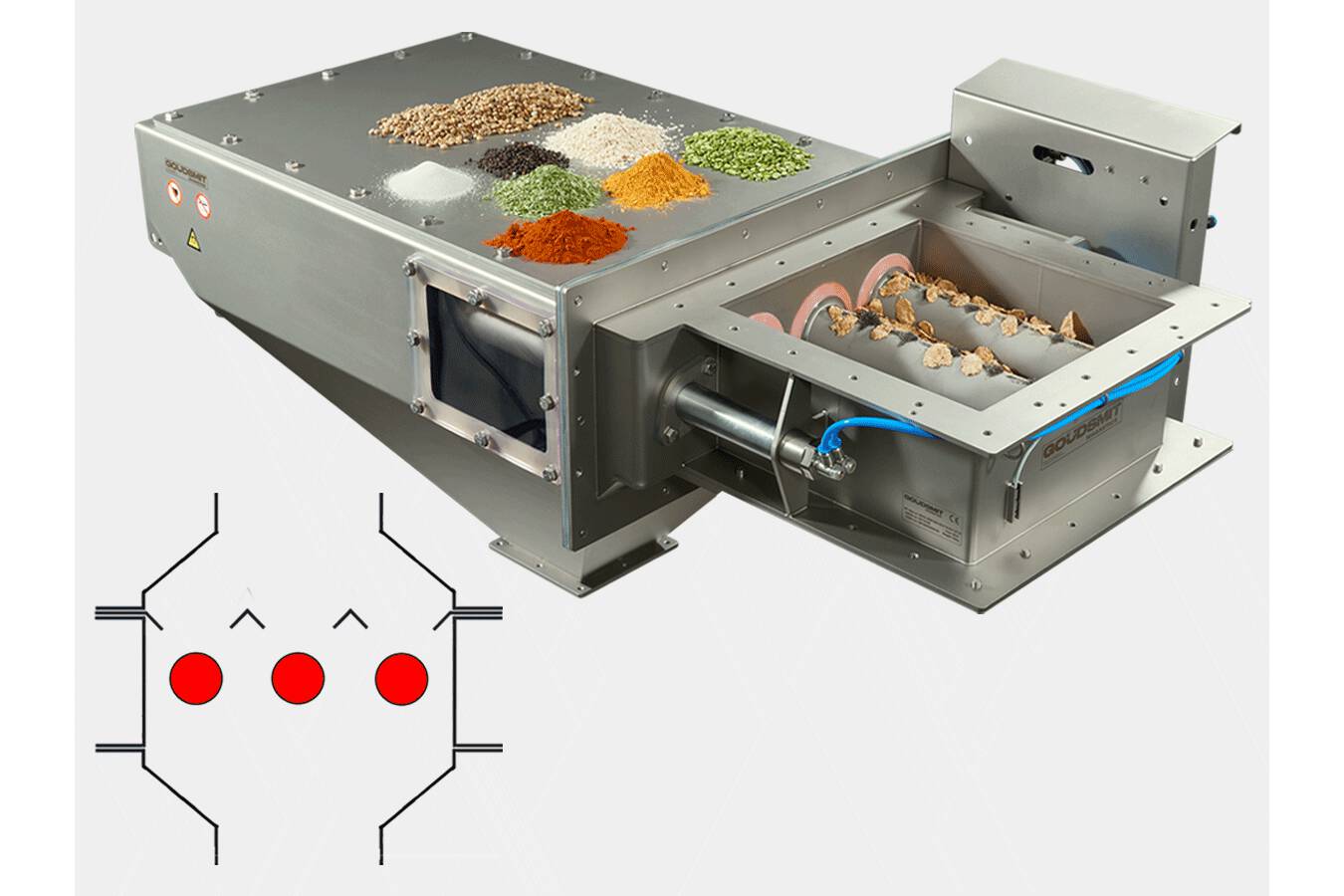

Magnetic separator or metal detector?

About magnetic filtering, magnetic separation, several ways to remove metal foreign bodies from your product streams. Magnetic separators remove metal foreign bodies from your product streams.

Metal foreign bodies ’contaminate’ your product, and they can also cause severe damage to your machinery. Rejection of batches is costly, but it can be even more costly if the foreign bodies are not removed, making it necessary to conduct a product recall. You will then be faced with huge costs and reputation damage.

Examples of metal contaminants / foreign bodies: staples, nails and screws, bolts and nuts that have vibrated loose, wear of the moving steel and stainless steel machine parts and rust particles (corrosion).

Magnetic separators filter and remove metal contaminations from your product streams, in order to guarantee high product quality and prevent damage to machines.

Magnetic separator or metal detector?

A magnetic separator filters/traps (and later removes) or immediately removes the metal contaminants from the product flow. Magnetic separators cause practically no product