Two Companies share a Common Philosophy

A good Basis for a Successfull Collaboration Zollikofer is an international logistic and commercial business for saw by-products, used, forest and energy wood with headquarters in Bad Wurznach. Since 1966 Zollikofer has been successfully active in wood logistics and trade. With five locations for wood processing and storage all over Germany, Zollikofer has been one of the market leaders for years. ”We understand our customers as partners to whom we forward goods of the highest quality and at reasonable prices as quickly as possible. Due to our well thought-out and proven processing and logistic processes, we not only secure the quality of our raw materials, but also the complete satisfaction of our customers”, said Wilfried Zollikofer regarding the corporate philosophy and image.

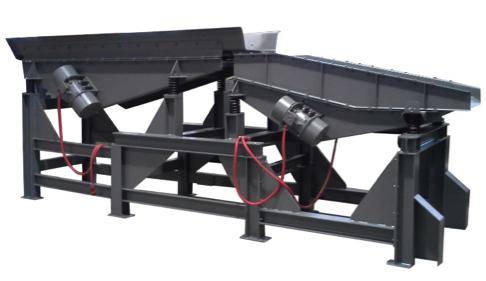

Since 2013 the company uses processing technology from HAAS at two locations. The processing plant at the location Riedlings was commissioned in October 2013. So far 87 500 tons of waste wood have been processed in 2500 operating