50 years of REMBE – with empathy and heart, at any time and worldwide

After fifty years of business, people often look back at the history, at old pictures, brochures and reports. But in REMBE’s anniversary year things are different...

Because here (today just as 50 years ago) it is the people who shape the corporate spirit and make REMBE what it is today. Stefan Penno, Chief Executive Officer REMBE GmbH Safety+Control explains: ”We trust each other, see the best in people and believe in each person’s individual strengths. Because humans are what matters to us.”

Bernhard Penno founded the company in 1973 as a sales office for rupture discs – initially as a one-man business in his garage at home. Just a few years later, new rupture disc designs were being manufactured in the company’s first production hall. In 2005, Stefan Penno, the son of the company founder, took the reins of the business. Today, REMBE employs 340 ”RFM” (REMBE family members) in over 90 countries and with 10 subsidiaries.

To mark its anniversary year, REMBE has come up with some ”special activities”. This year’s celebrations are entirely in keeping with the above motto. They will start with an international REX conference for all RFMs worldwide. After a long break due to the coronavirus pandemic, the conference can finally resume this year at the newly renovated company headquarters in Brilon, Sauerland. This will be followed by the REMBE Family Day, thus ensuring that the anniversary year will be commemorated in style.

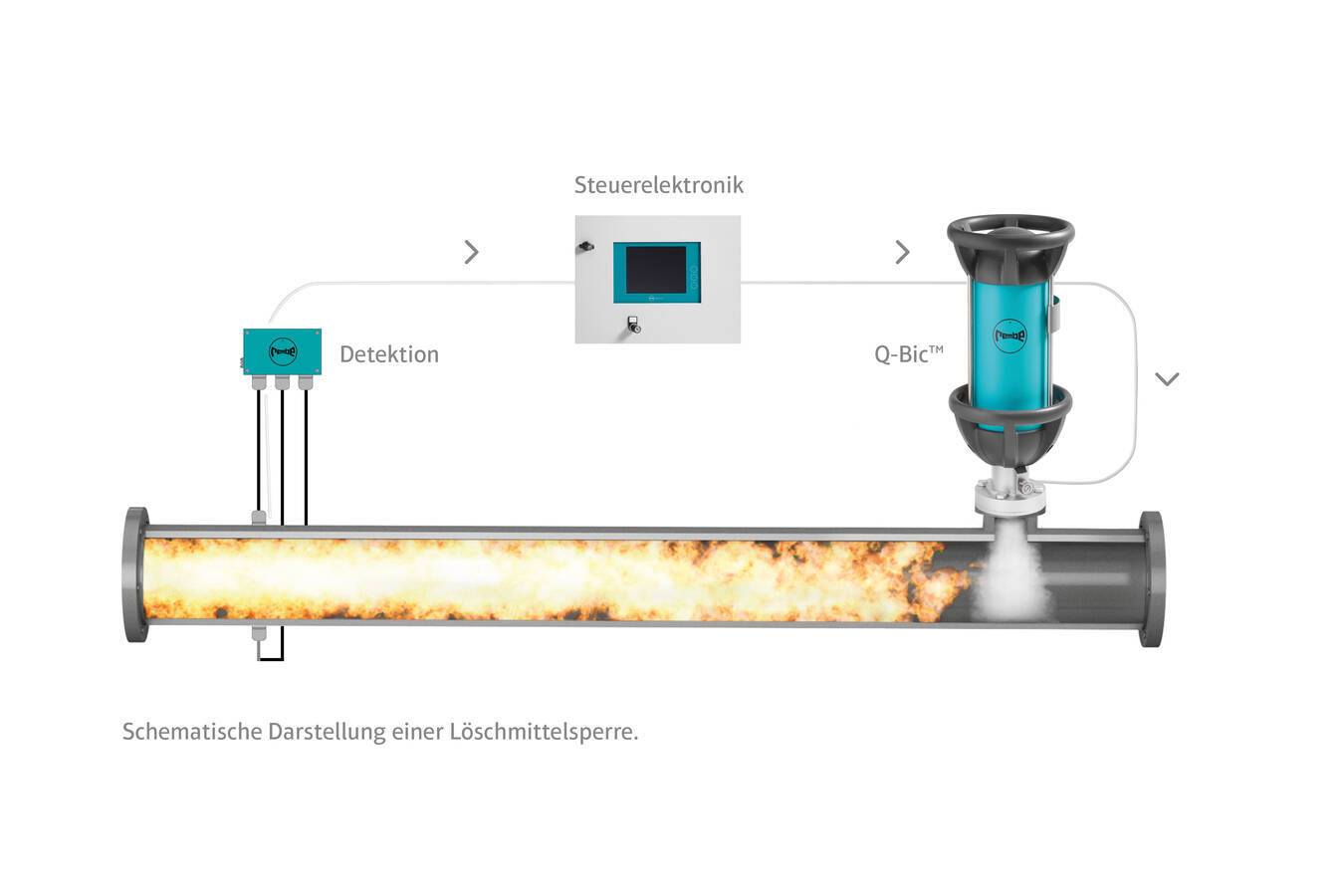

REMBE rupture discs and explosion protection systems safeguard processes in all industries around the world and help to save lives every day. REMBE wouldn’t be REMBE if we didn’t think outside the box, says Stefan Penno. With this in mind, several initiatives have been launched in recent years. For example, the RFMs involved in the REMBE green initiative are looking for improvement potential, determining which environmental aspects could be given greater attention to benefit customers and partners, and evaluating ways to ensure natural resources are handled responsibly – and are thus making a small contribution to protecting our planet.

After the REMBE WeltWald was launched last year as a major project of the initiative (8 hectares of forest are being reforested here), there is another campaign for the anniversary. 50 years - 500 trees.