interVIB vibratory screen improves scrap metal quality

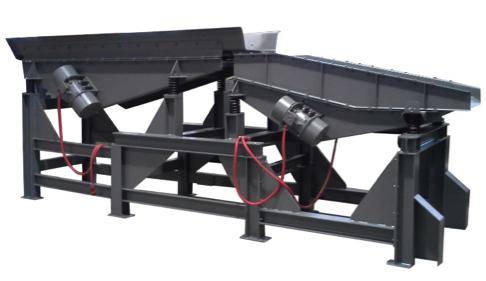

German based interVIB GmbH known as developer and supplier for vibratory conveying and screening equipment has delivered numerous Linear Vibratory Screens type VSL with special developed 3D-screening cassettes to various steel factories and scrap yards.

The task is to improve scrap metal quality, either provided from shears or shredders, by taking out fines, magnetic dust and non-ferrous material. Capacities from 40 to/hr up to 300 to/hr can be achieved depending on the screen dimensions.

The main focus is placed onto the special designed screening surface which is built from extra strong manganese steel. It is built as cassettes which can be easily exchanged and have a life span of over 18 months. Mainly 2-3 cassettes are inserted with cascades in-between, revolving the scrap. This ensures, that the fines laying on top of large scale parts will also be separated.

The robust designed main body of the screening machine ensures that also unexpected heavy parts or