The synthetics industry finds itself balancing between innovation and the growing demands for sustainability and efficiency. Synthetics are ubiquitous and play a vital role in our everyday lives. At the same time, there is increasing pressure to make processes more efficient and environmentally friendly. UWT provides tailored level measurement solutions to effectively help overcome these sustainability challenges.

Requirements and Solutions

Accurate level monitoring is essential in the synthetics industry – whether for the storage of granules, further preparation and processing in production facilities, or quality assurance. UWT sensors minimise production downtime, optimise material flows, and ensure consistent product quality.

Your Advantages with UWT

- Reliability and Flexibility

UWT sensors deliver precise measurement results even under challenging conditions – whether for granules, powders, or flakes. Thanks to Plug & Play functionality, they are intuitive to install and ready for immediate use. IO-Link allows quick adaptation to new materials and processes, while a wide range of process connections makes integration into existing systems straightforward.

- Innovative Technologies for Safety and Efficiency

Safety Features: Reliable measurements through advanced technologies such as interference signal suppression.

Visualisation Solutions: Real-time data for precise monitoring and improved control.

- Robustness and Durability

UWT sensors withstand extreme conditions such as temperature fluctuations, humidity, and abrasive materials. With Active Shield Technology, build-up is prevented – ensuring long-term precise measurements.

- Tailored Solutions for Challenging Applications

Whether for short measuring distances, contactless measurement through container walls, or dynamic processes – UWT offers the right solution for every requirement.

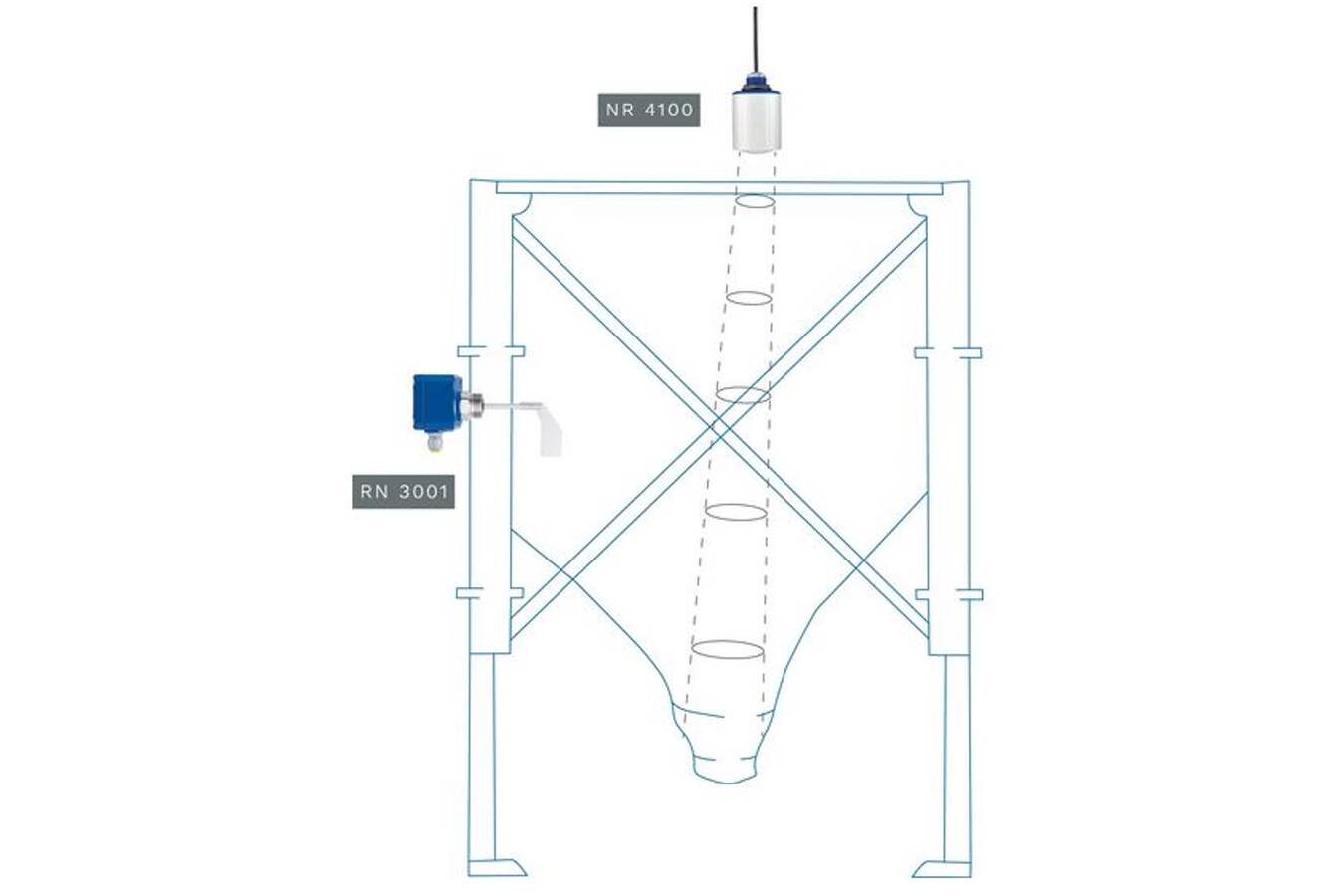

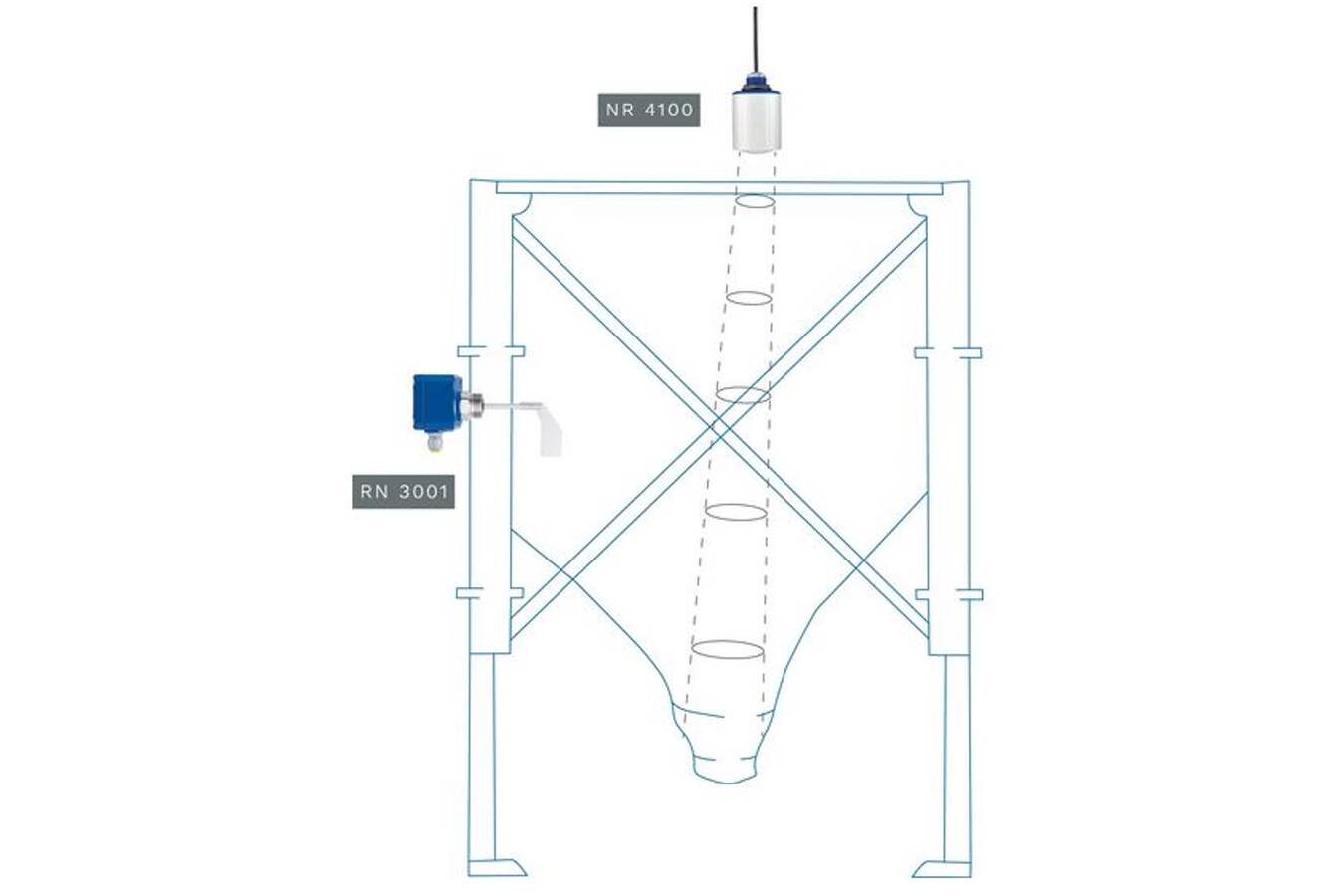

Application Example

Optimised Level and Point Level Measurement; Raw materials are often stored in textile silos, where full, demand, and empty detectors are sewn directly into the fabric using a flange. The Rotonivo® 3001 serves as a dust-tight rotary paddle switch for reliable demand monitoring.

Radar sensors, such as the NivoRadar® 4100, penetrate the textile fabric and enable continuous level measurement.

- Challenge: Lack of defined process connections, short measuring distances, difficult installation conditions

- Solution: Flexible sensor integration, precise measurements, interference signal suppression, and compact design

Discover in our brochure how UWT enhances quality and precision in the synthetics industry: Solutions for the Synthetics Industry.

Success Stories from the Field

UWT’s expertise is demonstrated through successful projects worldwide. For example, a solution was developed for a synthetics processor to monitor the fill levels of its silo batteries across multiple locations in real time. The sensors had to deliver precise and reliable performance despite varying properties of the synthetic granules, such as dielectric constant (DK), dust generation, and temperature fluctuations.

The applied combination of the NivoTec® 3500 for level monitoring, the NivoBob® 3100 electromechanical system for level measurement, and the Rotonivo® RN 3002 full detector enabled efficient production planning, reduced material losses, and increased operational safety.

This tailored solution highlights how these technologies help meet even the most challenging requirements of the industry.

Why Choose UWT?

- Precise measurement solutions for granules, powders, and flakes

- Quick and easy integration into your systems

- Maintenance-free and durable sensors

- Support for sustainable and efficient production processes

UWT – Taking your processes to the next level.

LEVEL. UP TO THE MAX.