The quality of asphalt largely depends on the precise dosing of its components. Accurate level and point level measurement is particularly crucial during the weighing process to ensure a consistent mixture. This is where robust sensors come into play, reliably operating even under extreme conditions.

During the weighing and mixing process, sensors are exposed to high temperatures, dust, abrasive materials, and chemical influences. Additionally, confined installation spaces and fluctuating material properties present common challenges. A durable, low-maintenance technology is therefore essential to minimise downtime and ensure a stable process.

Precise Measurement and Dosing in the Mixing Process

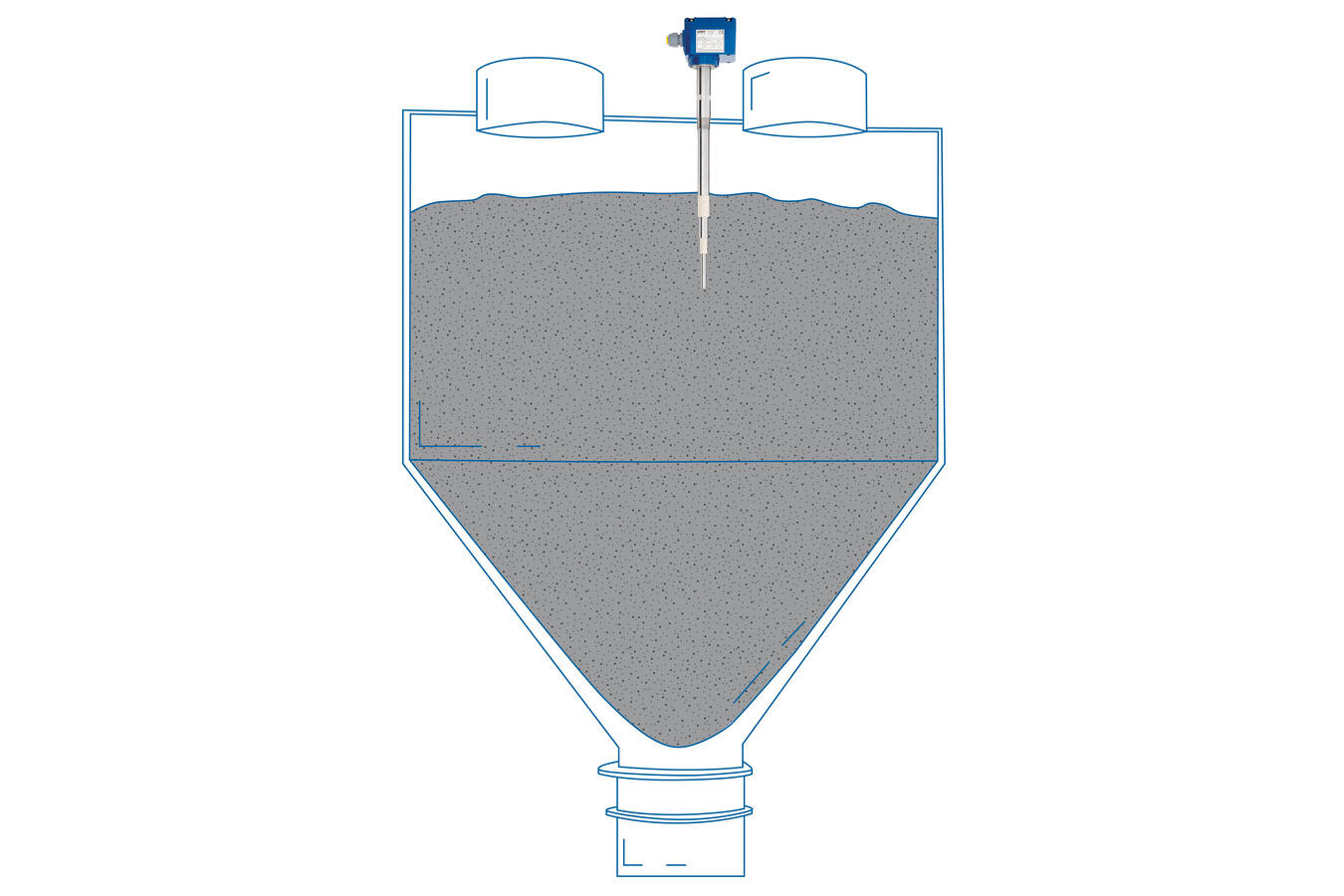

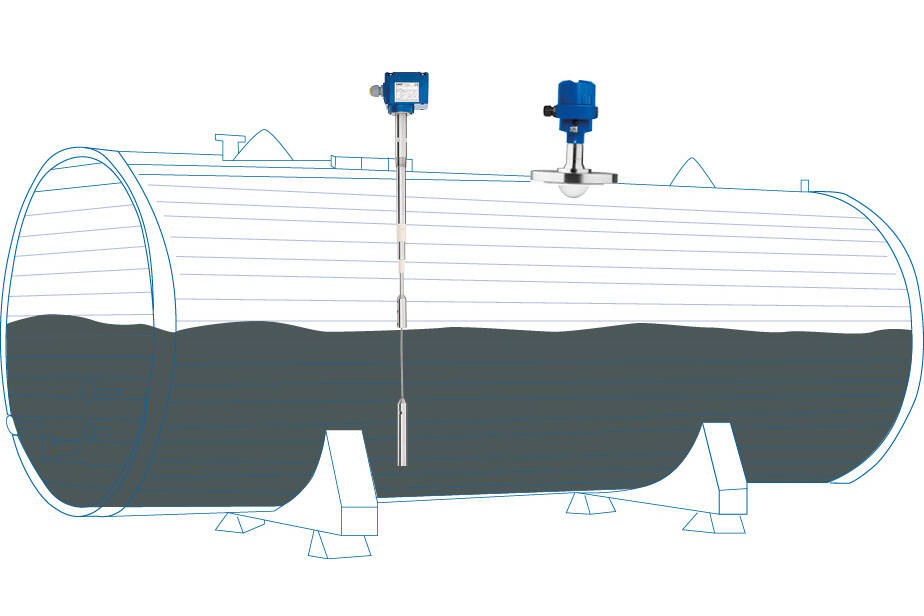

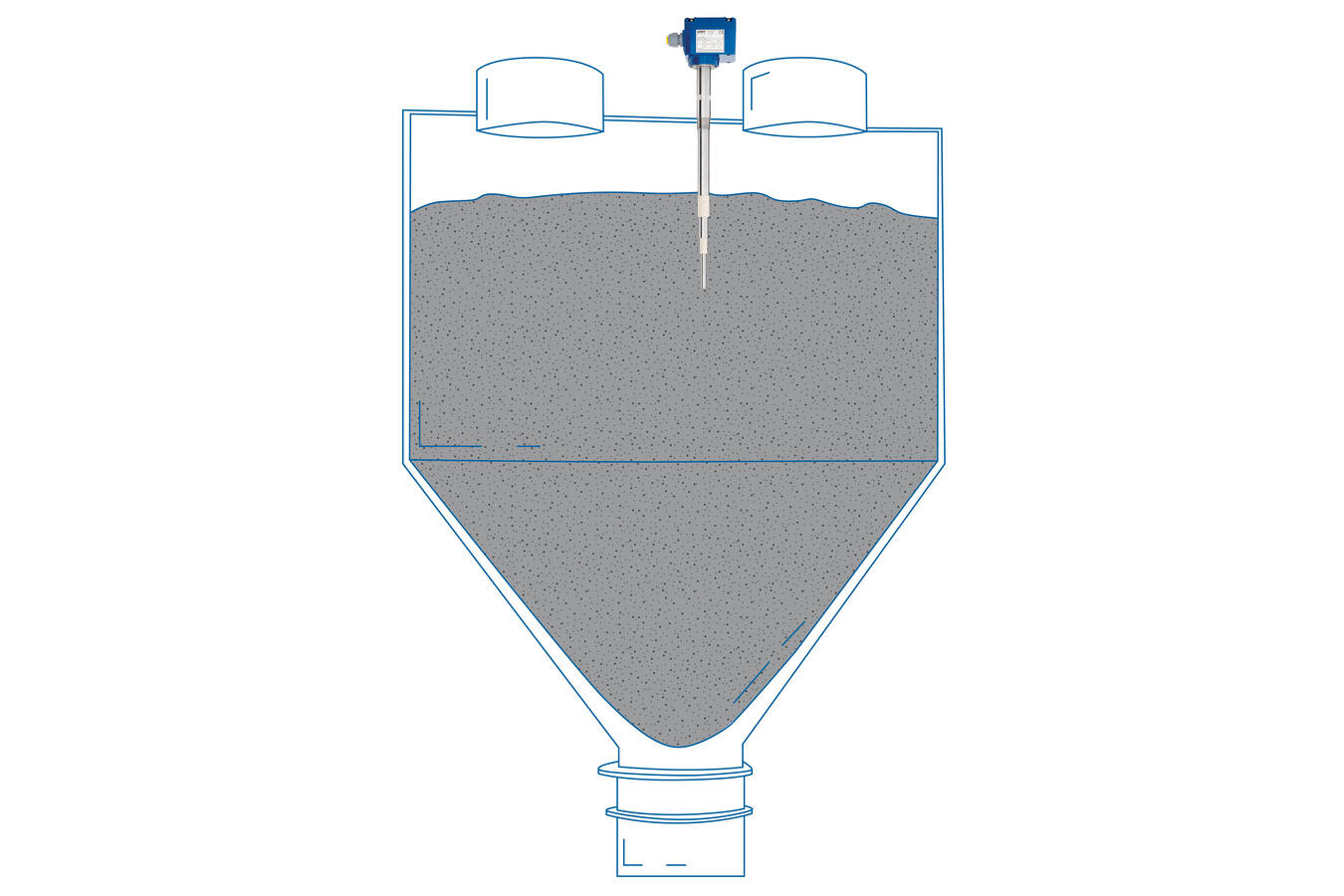

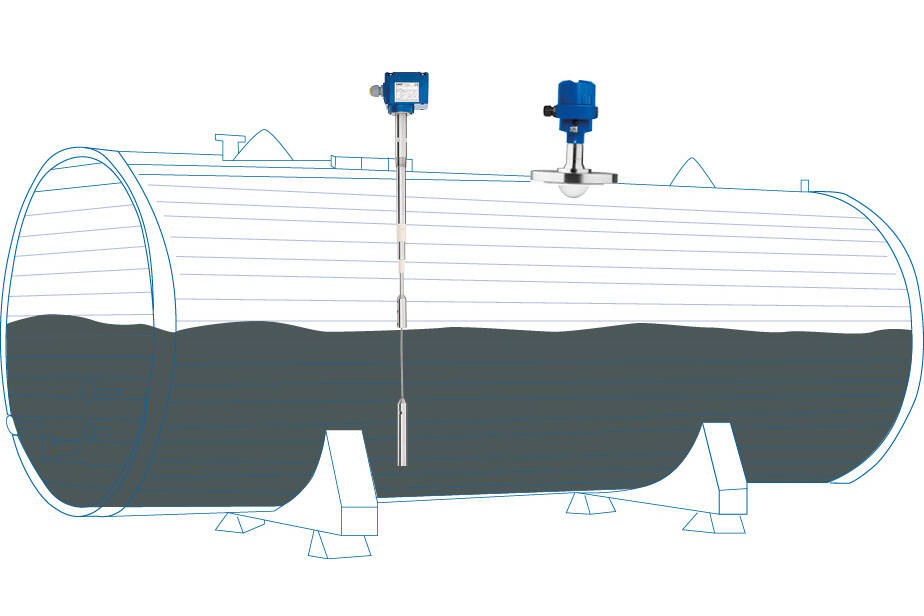

While the capacitive RFnivo® sensor provides a robust and adaptable solution for demanding point level measurement in asphalt production, the NivoRadar® – NR 8 ensures continuous and reliable level measurement in viscous bitumen. Even under extreme conditions such as high temperatures, build-up, and condensation, it delivers precise measurement results.

Key Benefits at a Glance

- Compact & Precise: Ideal for confined installation spaces, unaffected by material flow.

- Durable & Resistant: Withstands dust, heat, abrasive materials, and chemical influences.

- Minimal Maintenance Effort: Automatic calibration with RFnivo® ensures easy installation and long-term stability.

- NivoRadar® enables quick and straightforward commissioning via the UWT LevelApp, the integrated display, or PACTware.

Technical Highlights:

- Active Shield Technology (RFnivo®): Prevents build-up and deposits on the sensor.

- PTFE-Encapsulated Antenna (NivoRadar®): Chemically resistant and highly durable.

- High Load Capacity:

RFnivo®: Temperature-resistant up to +500 °C / 932 °F, withstands pressure up to 35 bar / 507 psi.

NivoRadar®: Variants available for up to 450 °C / 842°F and pressures up to 160 bar / 2,320 psi.

- Flexible Designs:

RFnivo®: Available in rod and rope versions, with remote housing for versatile applications.

NivoRadar®: High-temperature versions, robust flange connections, and a clip-on display.

- Certified Safety: ATEX approvals for dust and gas explosion-hazardous areas.

Industry Expertise for Demanding Applications

With decades of experience, UWT develops tailored measurement and monitoring solutions – even for complex processes such as those in the asphalt sector.

Download our industry brochure now for detailed solutions – learn more today.