Fine dust, explosive atmosphere – challenging conditions are part of everyday operations in grain processing.

Especially in mills, where large quantities of grain, meal or flour are handled and processed, the risk of dust explosions is real – and often underestimated. This makes the use of reliable, ATEX/ IECEx-certified level measurement technology all the more important.

Challenge: Level measurement in Ex zone 20/21

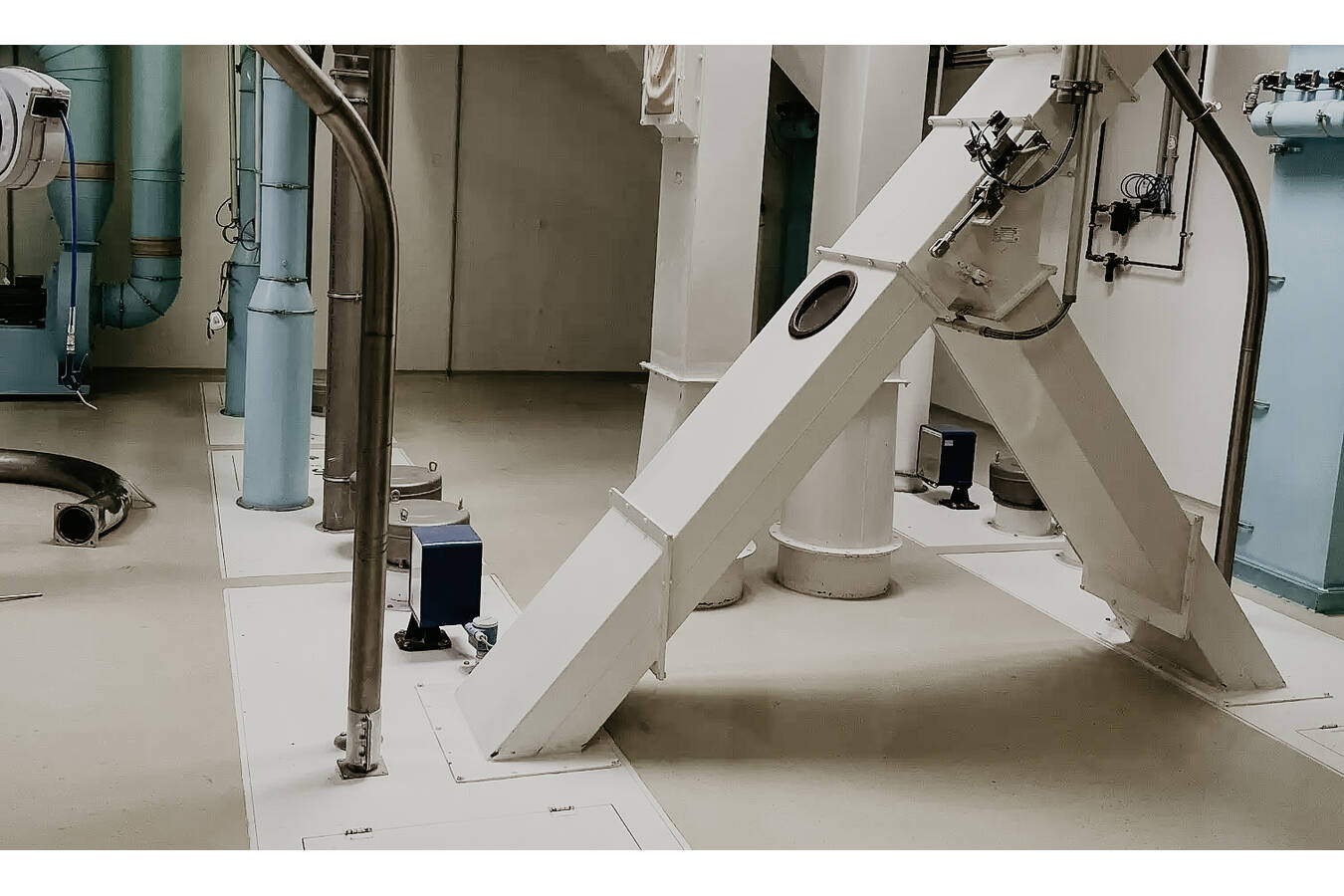

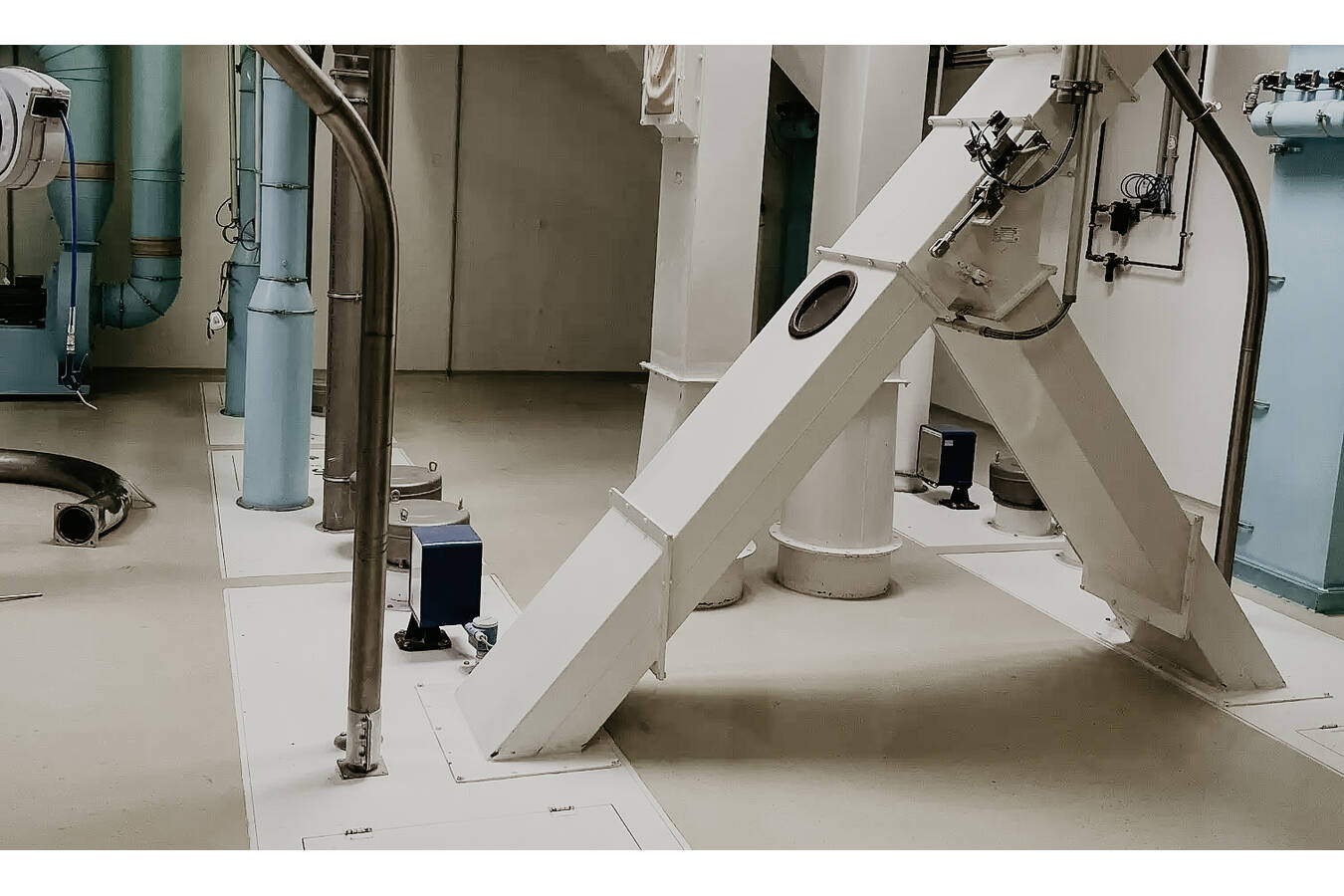

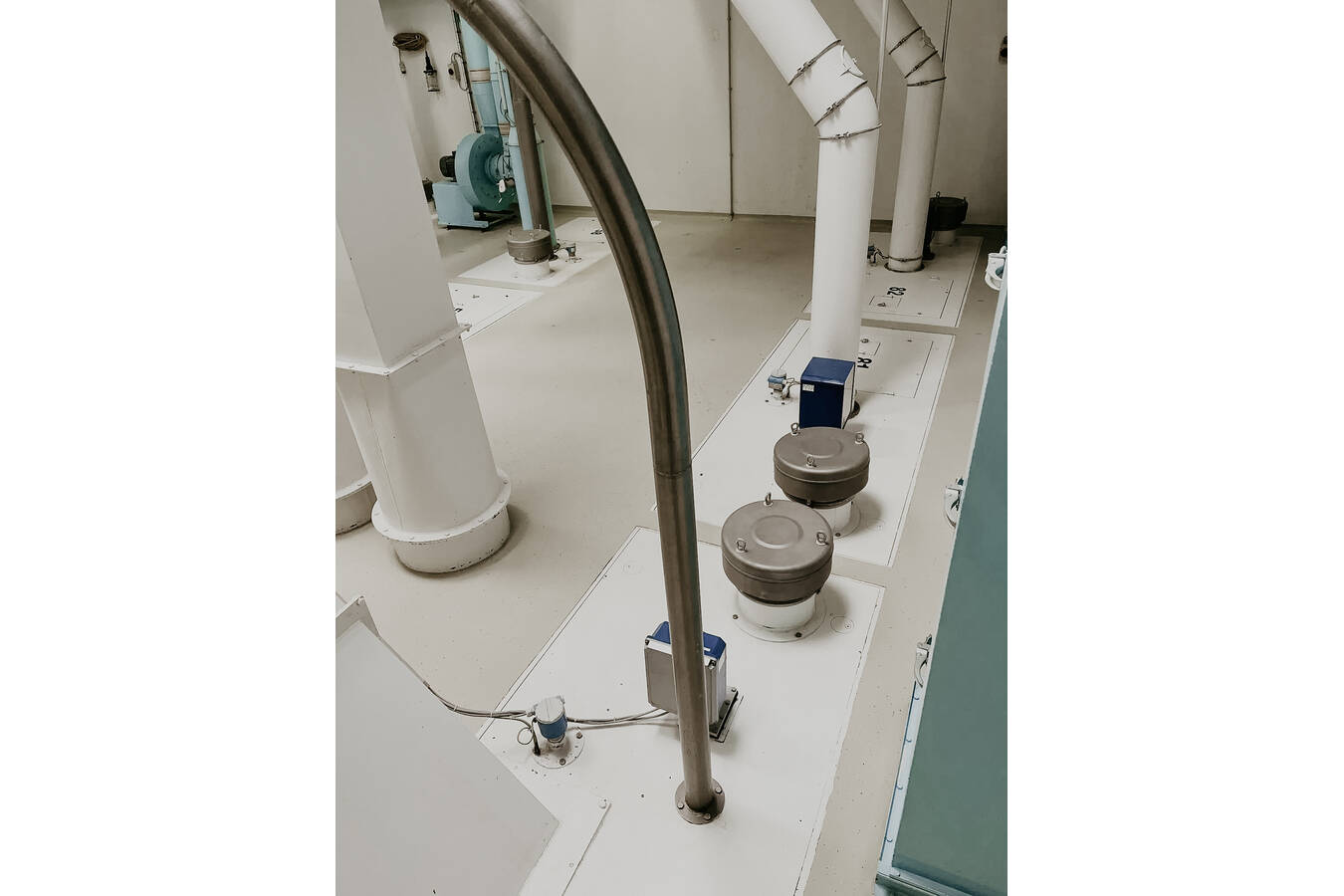

At a grain mill in Austria, intermediate storage in a 12-meter (39-foot) high silo had to be reliably monitored. The task: a combination of continuous level measurement and precise point level detection – to effectively prevent overfilling and material shortage.

Key requirements also included easy integration into the existing control system, low maintenance, and full compliance with explosion protection regulations for zones 20 and 21.

Additional challenges: heavy dust generation and temporary overpressure during the filling process.

The task with all these challenges and requirements is successfully solved with a system from UWT designed to handle exactly these conditions.

The solution: A powerful trio

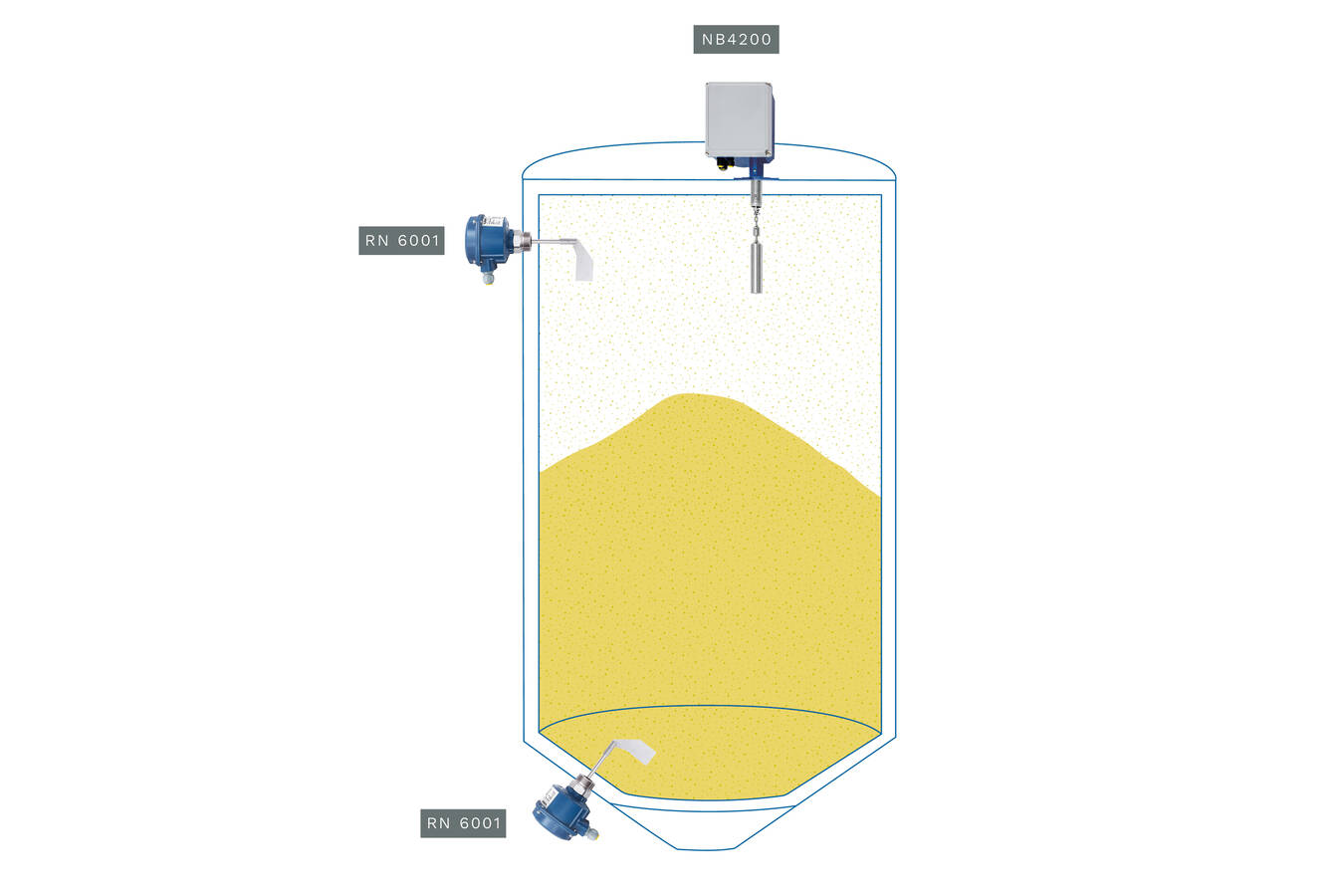

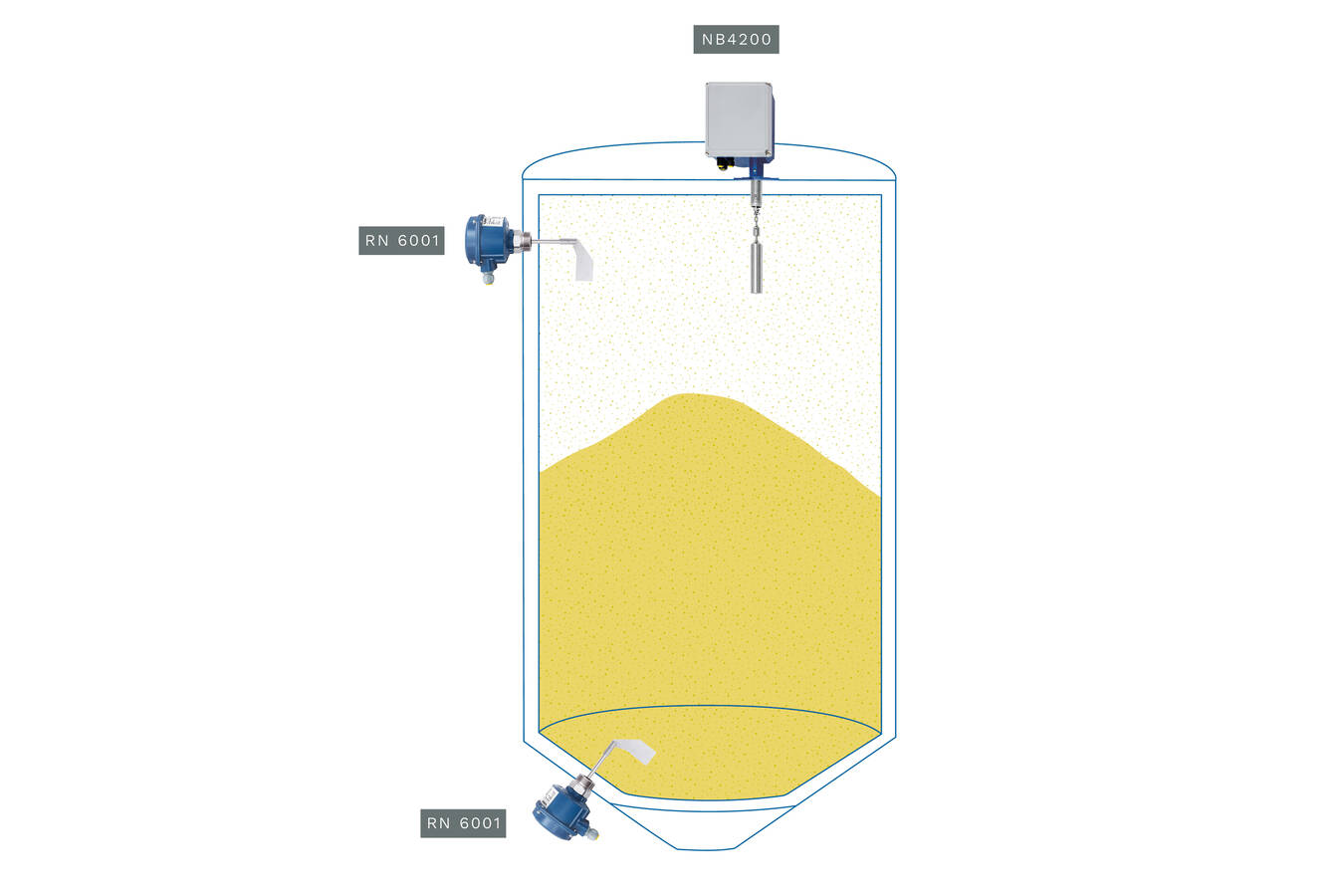

A powerful trio of the NivoBob® lot sensor, for continuous level measurement; the Rotonivo® point level switch, for precise point level detection with SIL 2; and the NivoLED® signal light, visible safety at-a-glance.

1) NivoBob® - NB 4200

Continuous level measurement, robust and precise; In this application, the electromechanical NivoBob® - NB 4200 ensures reliable level monitoring in the silo. With a measuring range of up to 30 m and international approvals in accordance with ATEX certification, it meets all requirements for safe use in hazardous environments.

- Dust-free thanks to integrated belt cleaner: The measuring tape is automatically cleaned during retraction – ideal for dusty conditions.

- Safe operation with dual-chamber housing: The separation of electronics and mechanics ensures long service life and maximum operational safety.

- Easy to handle: Flange mounting and simple integration make the NB 4200 a low-maintenance solution for continuous level measurement – including in Ex zones.

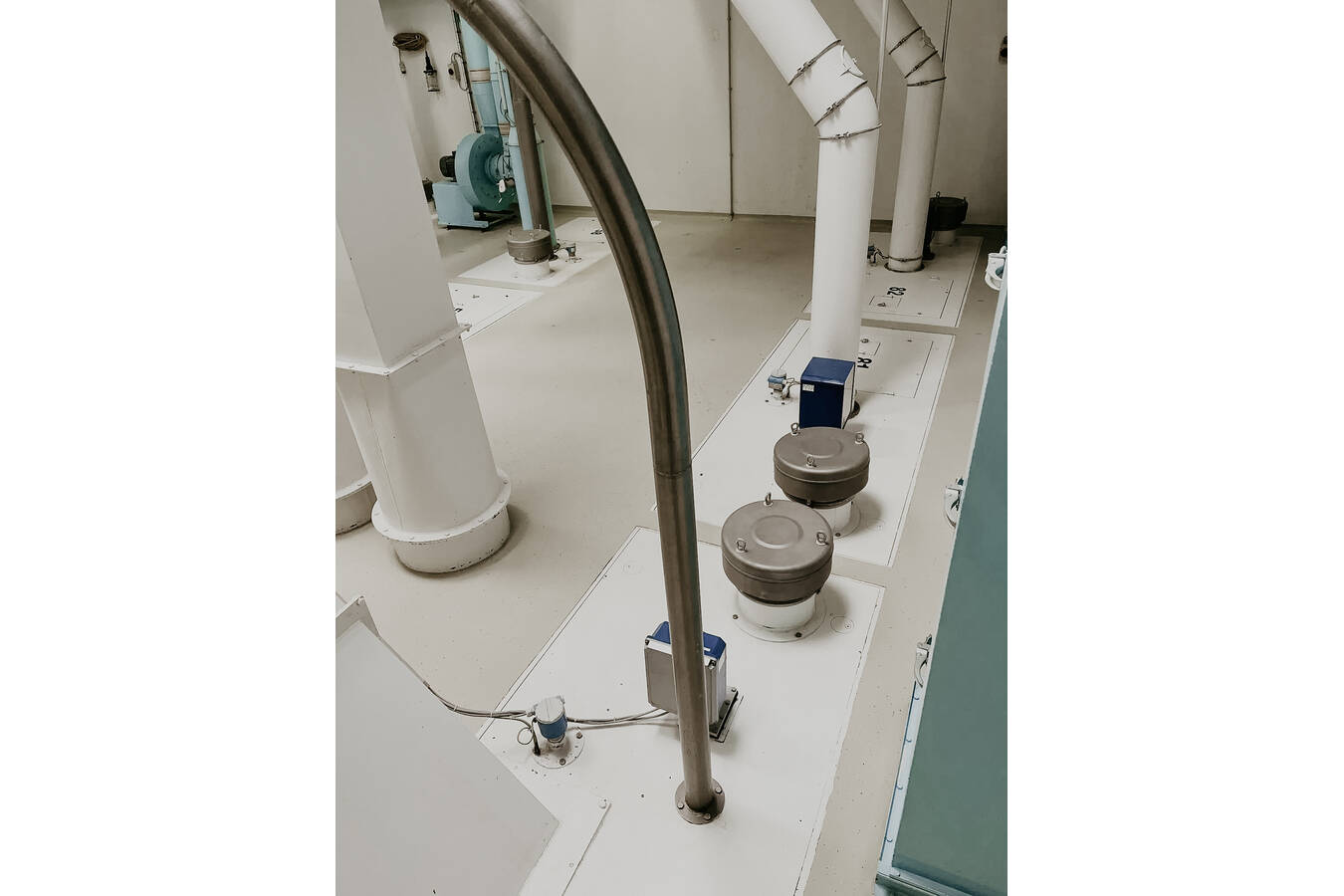

2) Rotonivo® RN 6001

Precise point level detection with SIL 2; The RN 6001 rotary paddle switch provides precise point level detection – serving as both a full and empty level sensor:

- Reliable with all bulk materials: Unaffected by material density or moisture.

- Flexible installation: Mounted horizontally for full detection, or at an angle from below for empty detection.

- Safety-oriented: SIL 2 certified according to IEC 61508 – ideal for safety-critical applications.

- ATEX and IECEx certified for Zone 20/21: Developed for safe operation in explosive atmospheres according to international standards.

3) NivoLED® NL 9

Visible safety at-a-glance; The measurement system is complemented by the unique NivoLED® signal light:

- Clear status indication: Red for critical, green for safe – the current status is instantly and clearly visible.

- 360° visibility: High luminosity with minimal power consumption – ideal for use in dusty environments.

- Certified for hazardous areas: NivoLED® is internationally approved for explosion protection – perfect for safe operation in Zone 21 and equivalent hazardous locations worldwide.

- Extremely durable: Mechanically robust and resistant to weather conditions and aggressive chemicals – thanks to its PVDF housing.

- Flexible integration: Can be mounted directly on the sensor or as part of an existing system – ideal for retrofitting, whether on control cabinets or process control panels.

Reliable measurement – even in dusty conditions

Conclusion: With the NivoBob® - NB 4200, the Rotonivo® - RN 6001, and the NivoLED® - NL 9, UWT offers a proven solution for safe and reliable level measurement in grain processing. The devices are robust, low-maintenance, easy to integrate, and meet all explosion protection requirements.

For maximum safety in mills, feed plants & more – in use around the world.