Although all technologies serve the same basic purpose – the separation of particles by size – they fundamentally differ in their construction, operation, and applications. The right choice can not only increase productivity but also minimize maintenance and downtime, which is crucial in today’s competitive industrial landscape. Below, we’ll look at the differences between conventional vibratory screens and direct-excitation screen machines to help you make your decision.

Conventional Vibratory Screens: How They Work

Conventional vibratory screens operate with an oscillating motion transmitted to the entire screen frame. This movement is generated by eccentric shafts or unbalance motors, ensuring the material advances on the screen surface and particles can fall through the mesh.

Advantages of Conventional Screens:

- Simple design

- High throughputs

- Flexibility

Disadvantages of Conventional Screens:

- Inefficient separation with low vibration amplitudes

- Higher maintenance costs due to high wear

- High energy consumption

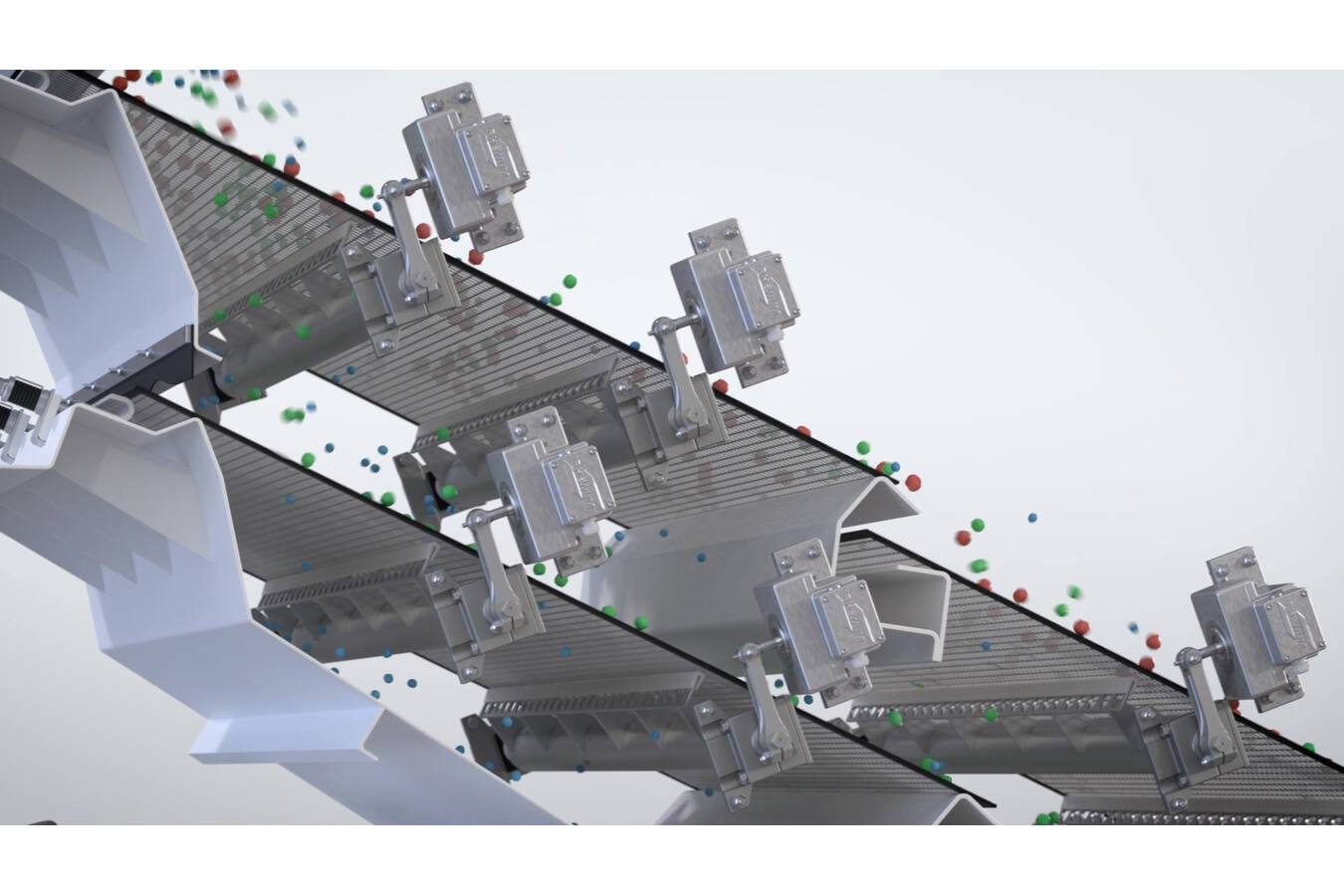

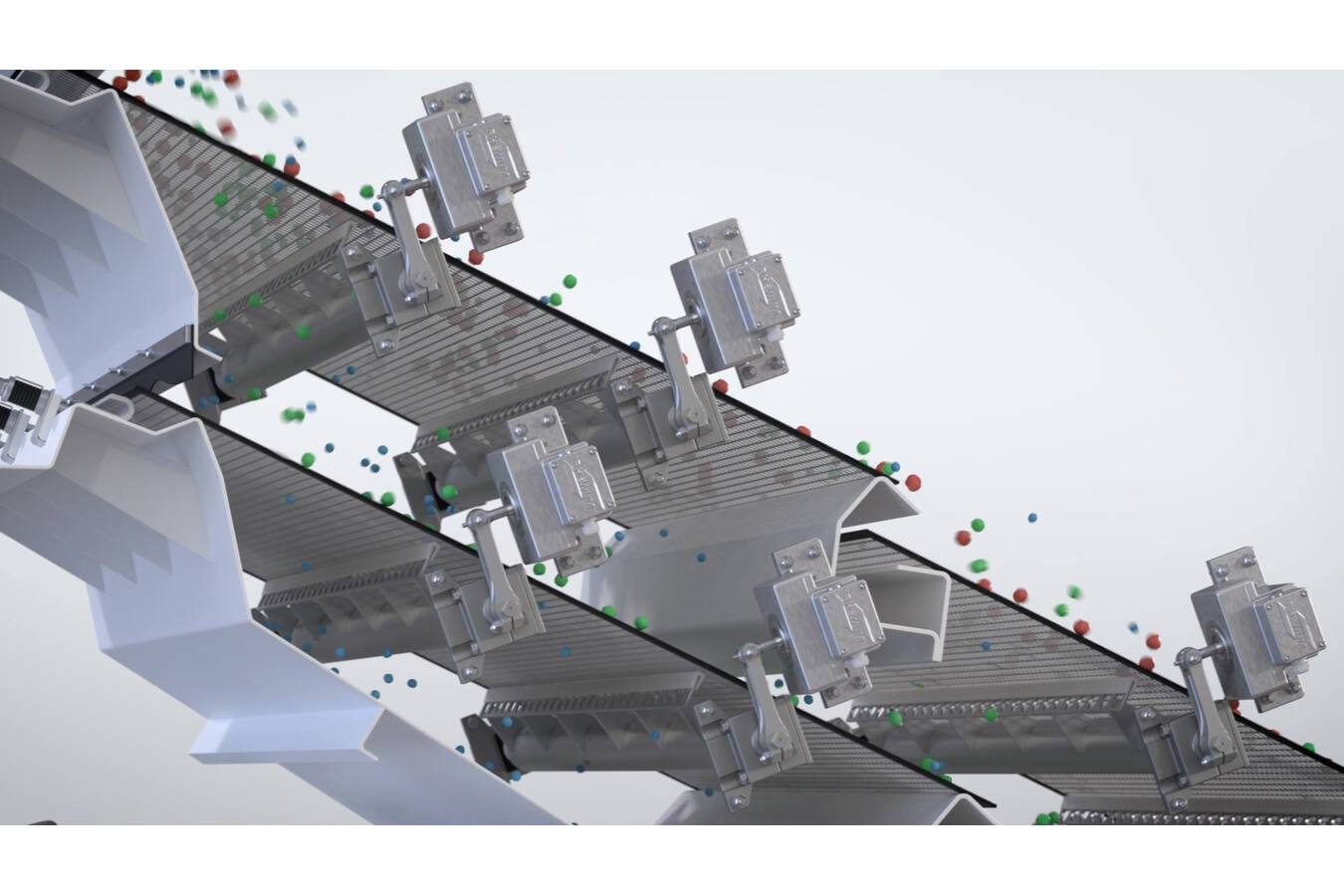

Direct Excitation Screen Machines

In contrast to conventional vibratory screens, this technology directly excites only the screen mesh. This is achieved by special electromagnetic drives, known as ”Powerpacks.” The screen frame itself remains static.

Advantages of Direct Excitation:

- Higher efficiency for fine separations

- Lower mechanical stress and longer lifespan

- Ease of maintenance

- Energy savings

RHEWUM Solutions and Advantages:

- High throughput capacity with models like the RHEsono®, RHEmoto®, or RHEfino®

- Low operating costs due to high-quality materials

- High operational reliability due to modular design

- Flexible adjustment of vibration parameters during operation