Safe storage and reliable monitoring of caustic soda in a dairy application

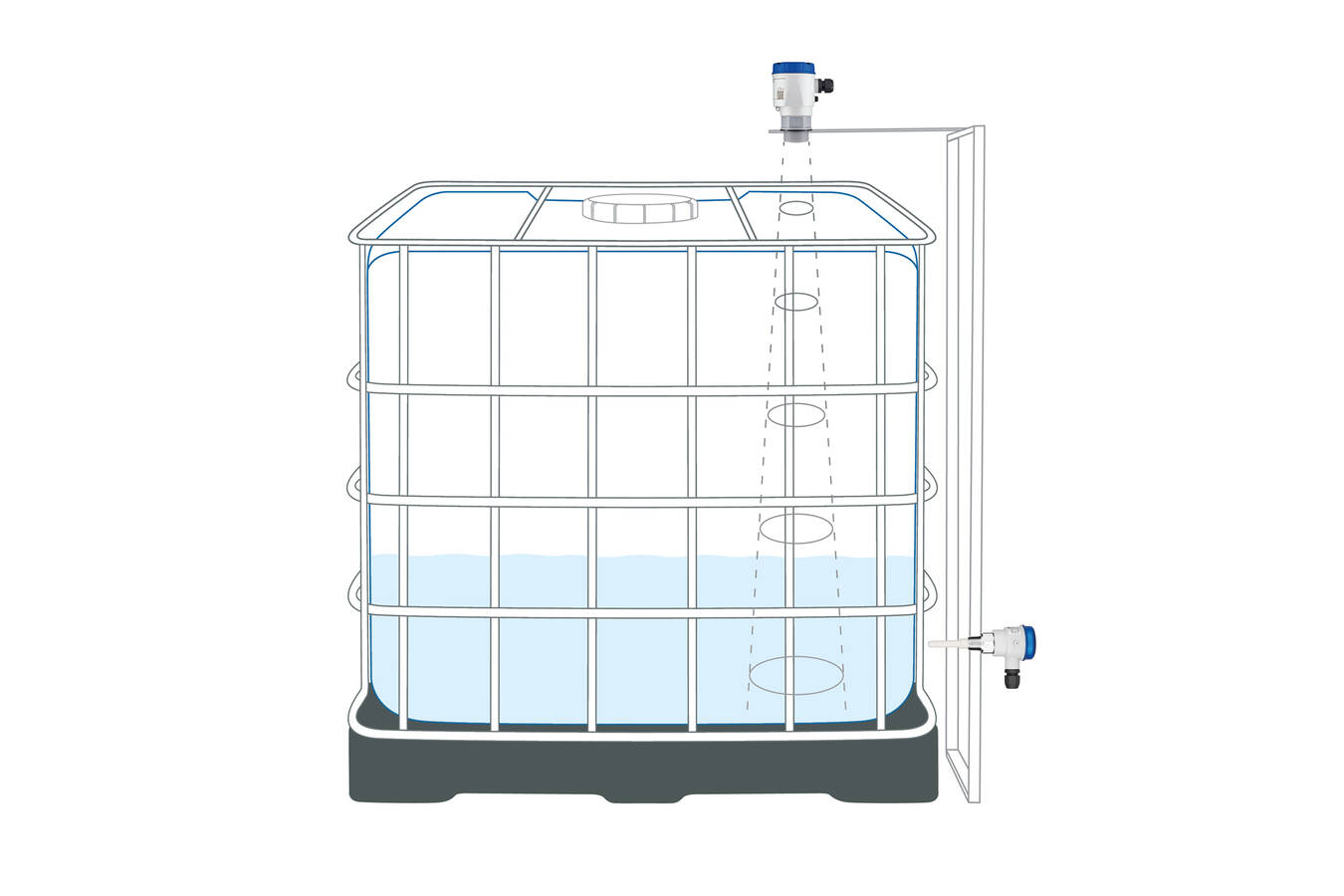

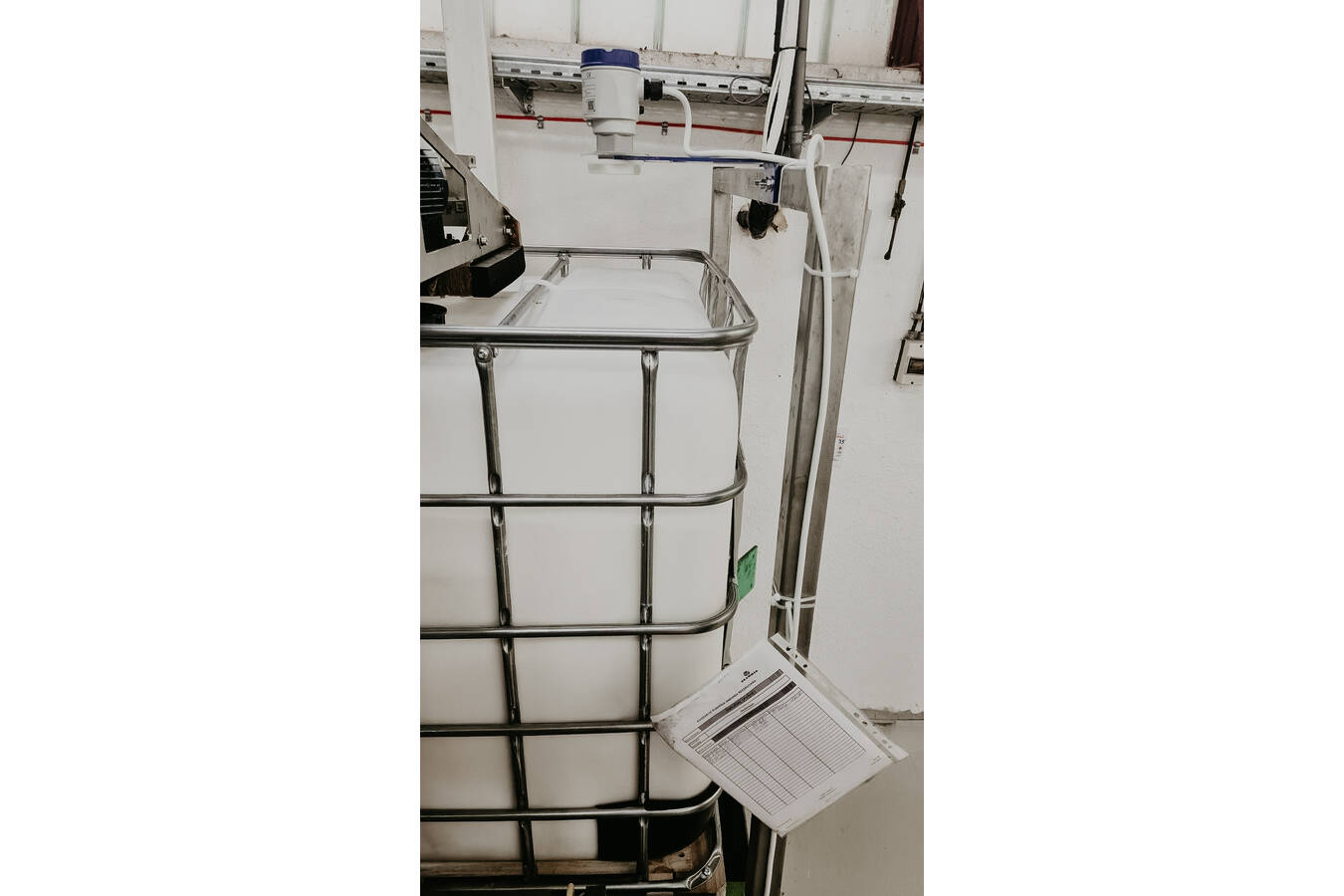

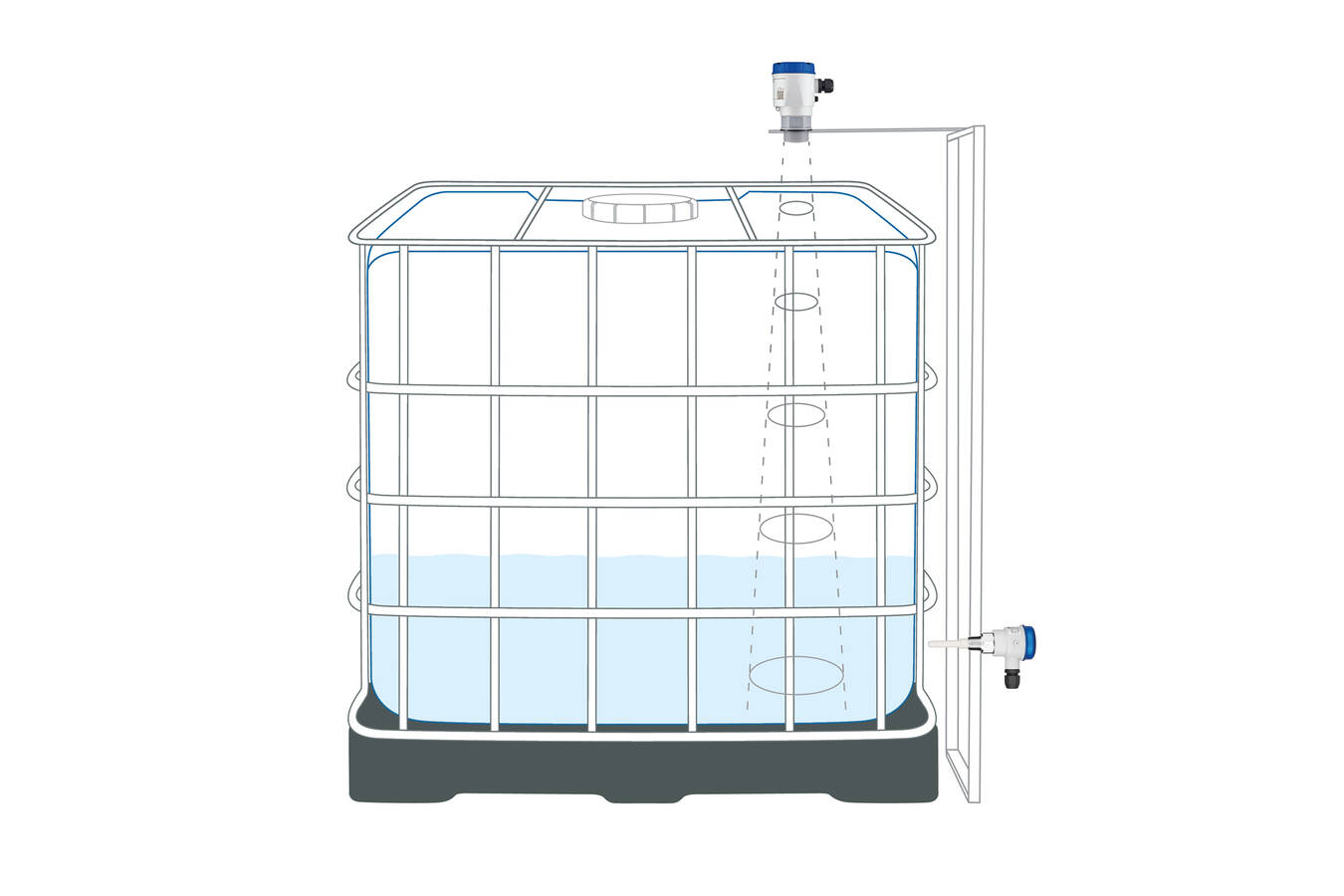

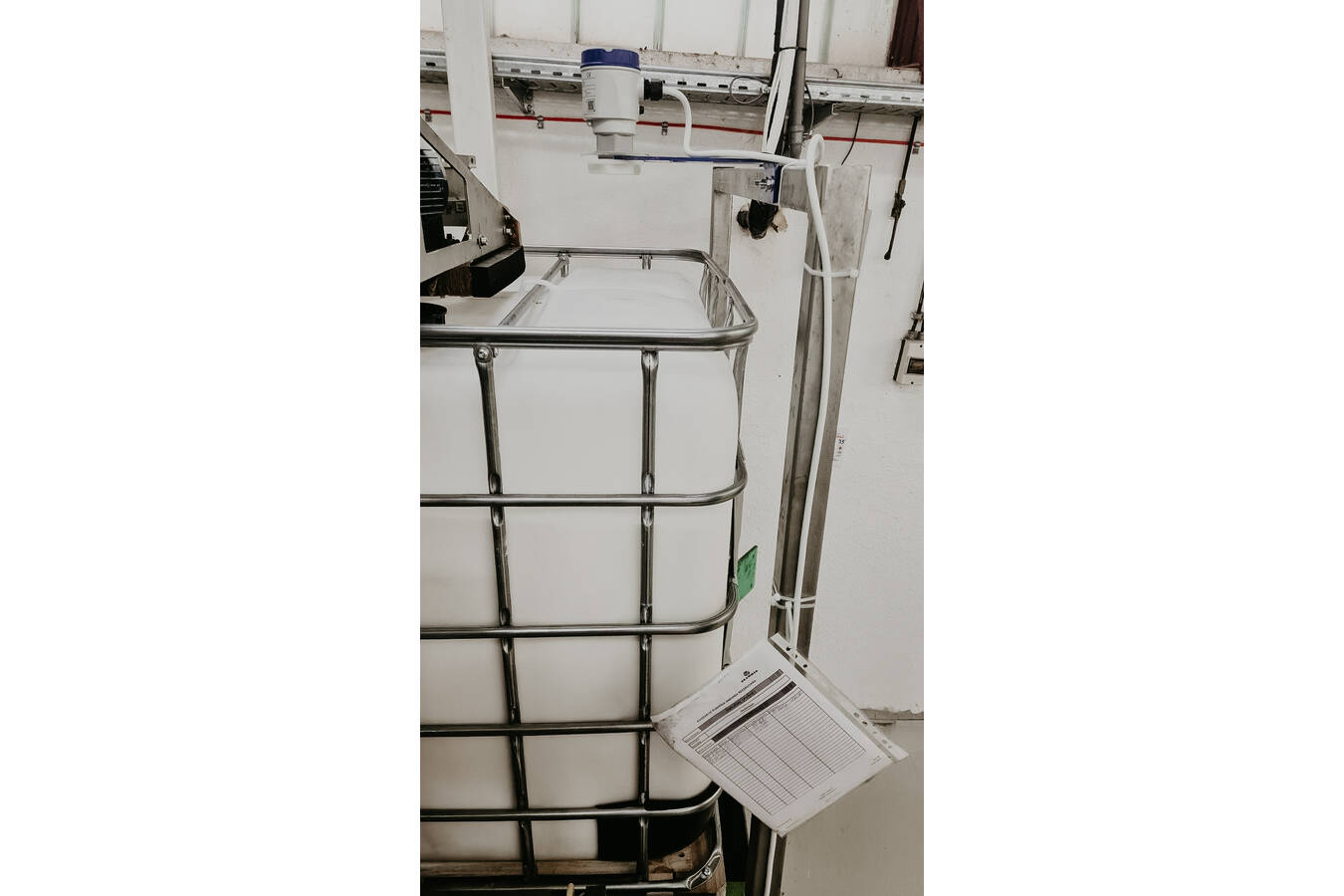

UWT has introduced a smart, non-contact level measurement solution for aggressive media stored in Intermediate Bulk Containers (IBCs). This system uses external sensors, eliminating direct contact with corrosive agents like caustic soda for safer, flexible, and more sustainable monitoring in plants.

Safe and Flexible Monitoring of Aggressive Media

Smaller dairies often use IBC containers for aggressive disinfectants like caustic soda (NaOH) instead of large stationary tanks. This practical approach allows the medium to be diluted and fed into cleaning-in-place (CIP/SIP) systems. UWT’s solution provides non-contact monitoring from outside the tank, ensuring a safer and more flexible operation.

Non-Contact Continuous Level Measurement

The continuous level measurement is handled by the NivoRadar® NR 7100. This free-radiating 80 GHz FMCW radar sensor is mounted vertically above the container. Its narrow 8° beam angle allows it to provide accurate and reliable results directly through the plastic tank wall, without making contact with the aggressive medium inside.

Capacitive Sensor for Empty Detection and Safety

For added safety, the Capanivo® CN 7120 capacitive sensor is installed externally at a low point. It functions as an empty detector, signaling when the container needs to be replaced. Its sensitivity can be easily adjusted to adapt to different liquids, ensuring flexibility across various cleaning agents.

Since both sensors are mounted outside the IBC, they remain completely protected from contact with caustic soda. This external installation significantly extends their service life and ensures safe operation over time.

Key advantages of the UWT solution include:

- Eliminates the need for large stationary tanks

- External installation safeguards instrumentation and extends service life

- Allows for simple exchange of empty IBCs

- System flexibility to accommodate different cleaning agents