Thanks to the growing demand for recycling, also the need for innovative recycling plants increases. In the years to come, waste will be a definition from the past. A significant number of recycled materials have become resources over the past decades, and the varieties continue to grow.

High-quality materials

Optimal recycling means selecting the ultimate installation design and applying high-quality materials, meeting your requirements. At Bezner, we have an in-house team of engineers for both mechanical and electrotechnical engineering. We are experienced in PLC programming and project management. Moreover, we have an in-house production facility.

Plastic recycling machines and plants

Apart from the argument of sustainability, given the oil price as a raw material for plastics, the reduced need for energy required to produce recycled plastics is another reason, economic this time, to use recyclables.

The most common types of discarded plastics for a profitable recycling installation are PET, HDPE, and LDPE. Also found in plastic waste streams is PVC. Recovering this kind of plastic is a sustainable way to reduce air pollution.

Innovative recycling processes

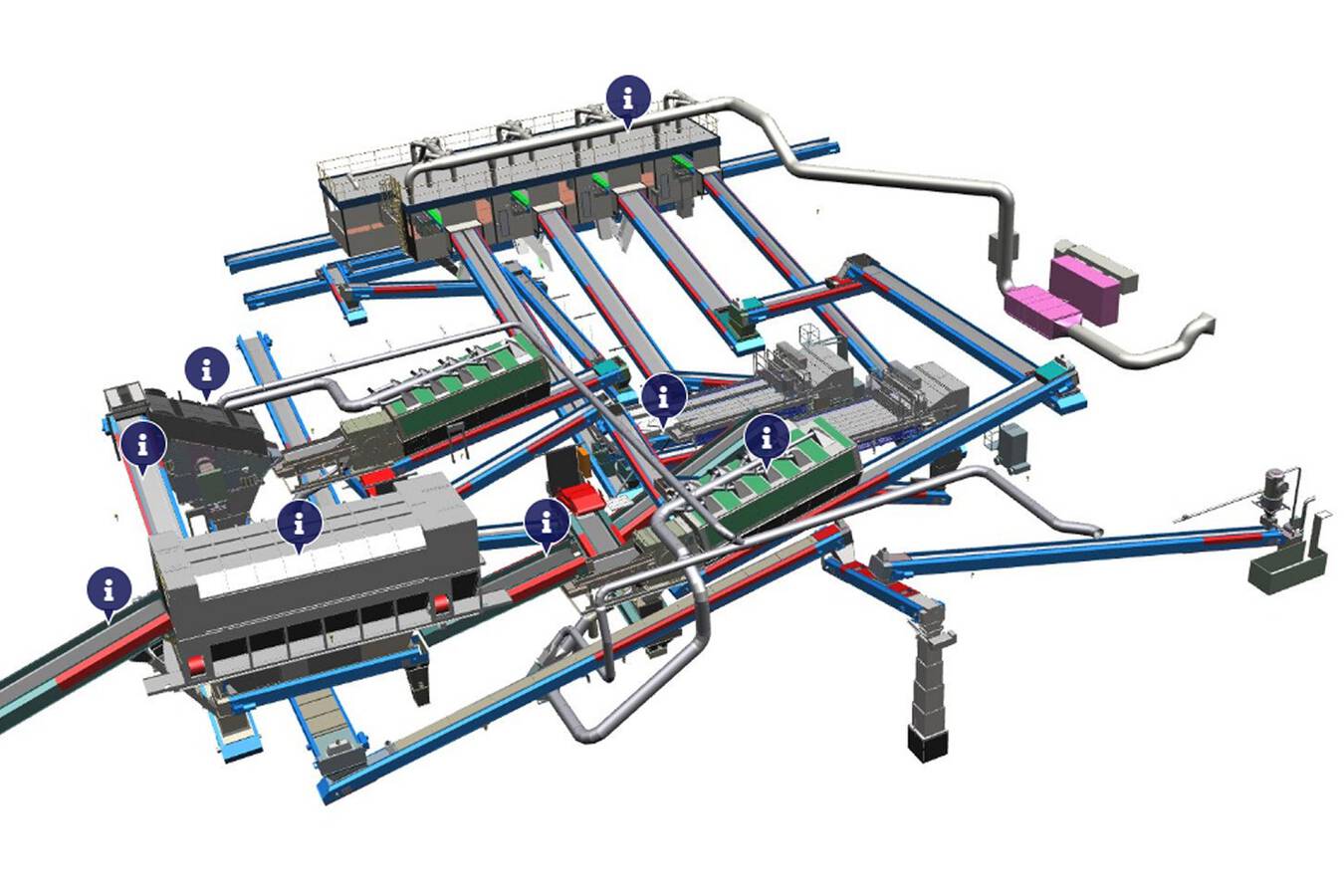

Bezner’s innovative recycling process includes (color) sorting, cleaning, shredding, granulating, melting and molding. We have the knowledge and experience to provide the technology for engineering, building, and installing a cost-effective and reliable installation to produce high-grade recyclables for excellent products further down the production chain.

Cooperation in plastic recycling

Bezner supplies sorting equipment for the waste management of all types of plastic waste. Further down the production line, B+B Anlagenbau (also part of the Heilig group) offers equipment for washing, drying, color separating, and packing the recycled plastics to be used as a raw material for newly produced products.

Bezner’s know how

For optimal waste recycling for our clients, Bezner engineers and builds waste management and recycling machinery according to customer’s recycling and sorting goals, dimensions and budget.

We build both conventional components and ingeniously tailored units. Specific equipment outside our range from secondary suppliers can be included. This way, our project management team offers a turnkey solution.

We operate in the following waste management and recycling industries:

- Bottom Ash recycling

- Commercial and industrial waste recycling

- Construction and demolition waste recycling

- Municipal solid waste recycling

- Glass recycling

- Paper and cardboard recycling

- Plastic recycling

- Single stream recycling