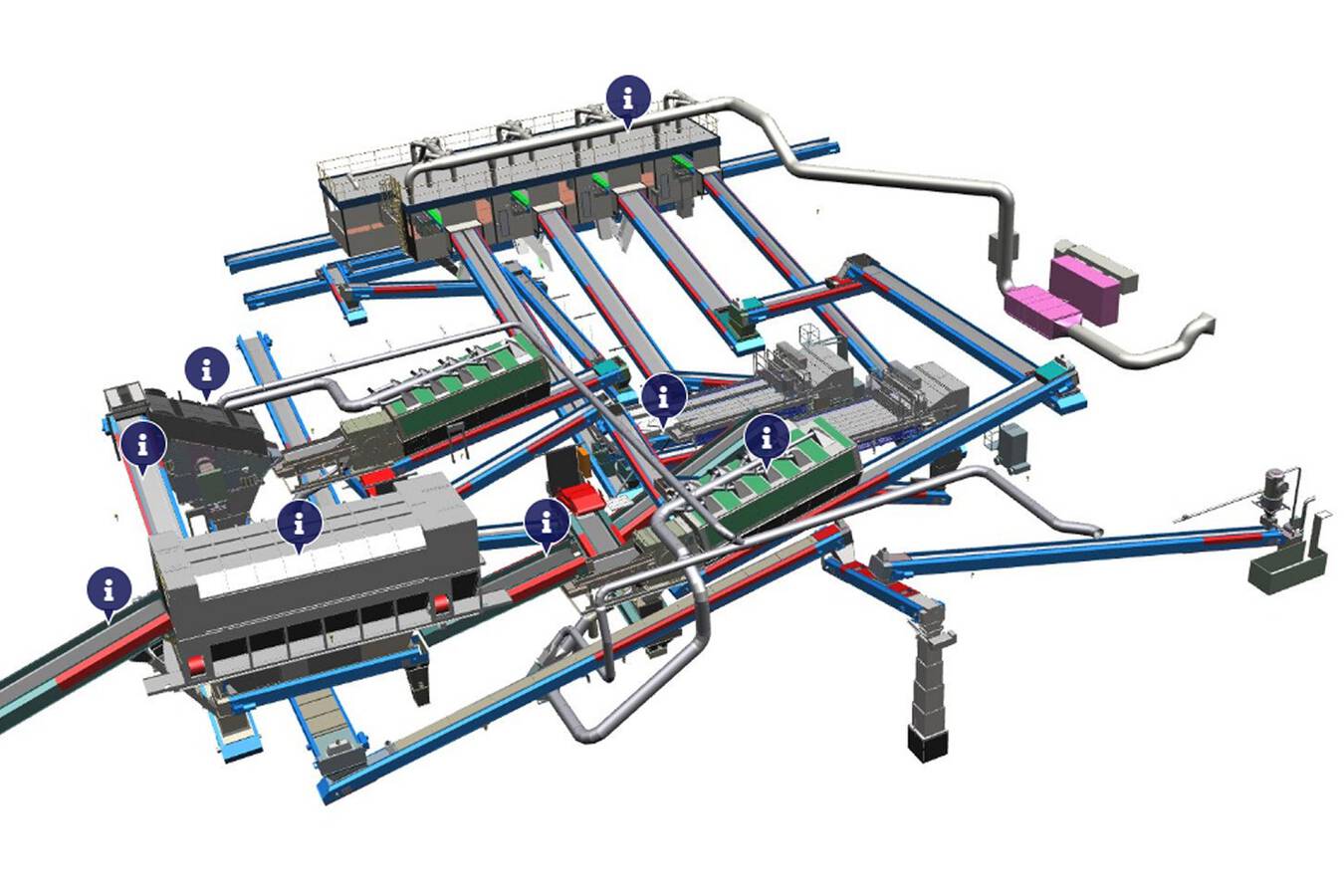

Recycling Solutions - Bezner engineers and builds waste management and recycling machinery according to customers’ recycling and sorting goals, dimensions and budget.

Waste-to-energy - Bezner knows every requirement to provide the most profitable, efficient and sustainable solution for your municipal solids waste recycling equipment.

Plastic recycling - Bezner’s innovative recycling process includes (color) sorting, cleaning, shredding, granulating, melting and molding of plastic waste.

Bulk waste - Bezner realizes installations with high throughput to separate RDF, residual components or recyclables such as metal, wood, and plastics.

Belt conveyors - Bezner is experienced in customized turnkey solutions, including belt conveyor systems that feeds, discharges, distributes, doses and accelerates.

Chain conveyors - According to your requirements for dimensions and conveyed materials, Bezner engineers a chain conveyor that fits your installation perfectly.

Elevator conveyors - Bezner offers a variety of conveyor lifts to convey materials vertically. We design smaller devices and heavy duty machinery for aggressive materials.

Vibrating Feeders - Bezner engineers, builds and supplies customized vibrating feeder for industries such as: Bottom Ash, Glass and Plastics. Feel free to contact us.

Bunker conveyors - Bezner engineers and builds bunker conveyors in-house. We offer a variety of shapes and dimensions.

Linear vibrating screens - Bezner engineers tailor-made components according to the sieving characteristics of the stream containing different materials.

Circulation vibration screens - Bezner is experienced in engineering both standard and customized designs for commercial-, industrial-, bulk-, construction and demolition waste.

Screening drums -

Bucket screens -

Air separators -