Magnetic separators remove metal foreign bodies from your product streams.

Metal foreign bodies ’contaminate’ your product, and they can also cause severe damage to your machinery. Rejection of batches is costly, but it can be even more costly if the foreign bodies are not removed, making it necessary to conduct a product recall. You will then be faced with huge costs and reputation damage.

Examples of metal contaminants / foreign bodies: staples, nails and screws, bolts and nuts that have vibrated loose, wear of the moving steel and stainless steel machine parts and rust particles (corrosion).

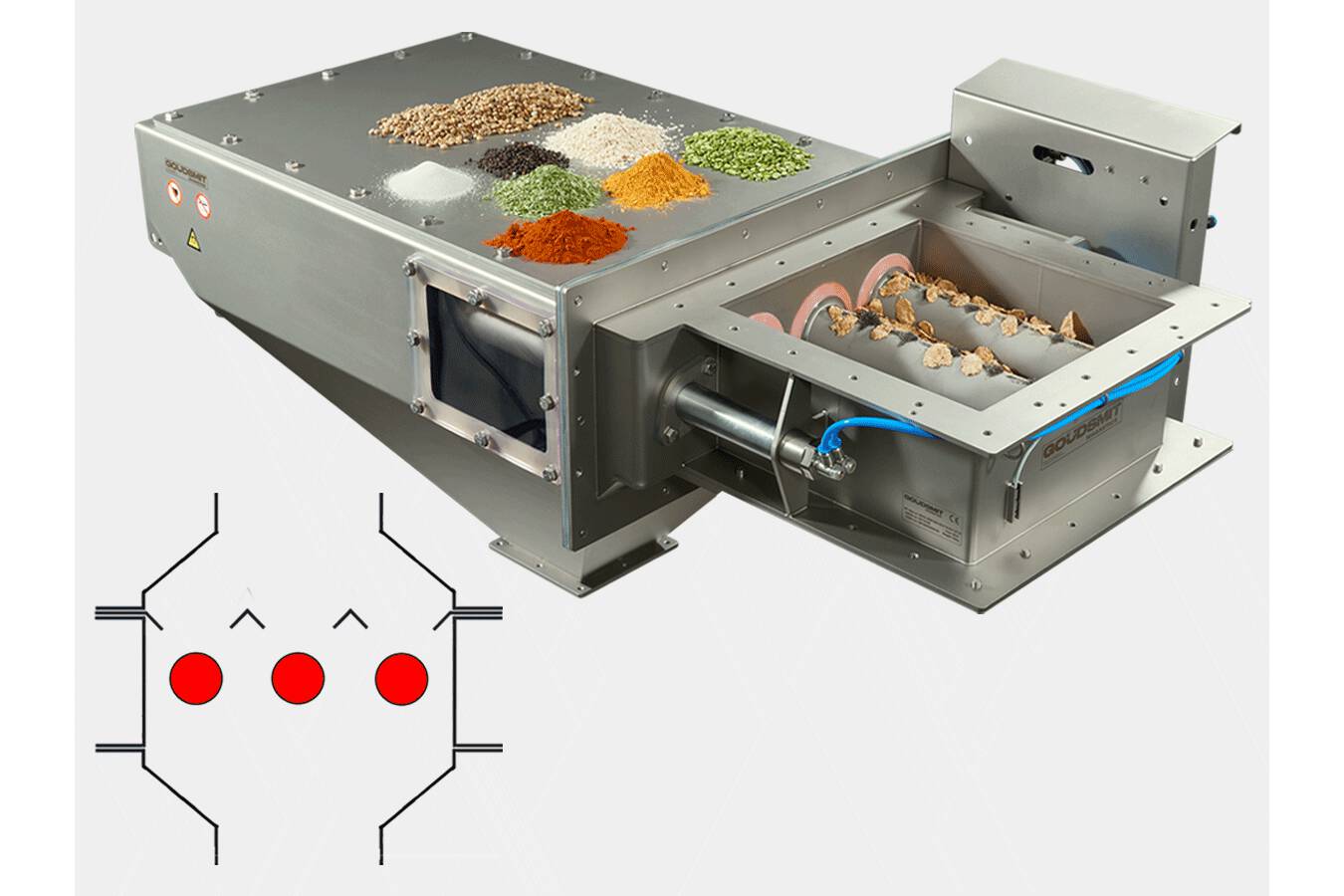

Magnetic separators filter and remove metal contaminations from your product streams, in order to guarantee high product quality and prevent damage to machines.

Magnetic separator or metal detector?

A magnetic separator filters/traps (and later removes) or immediately removes the metal contaminants from the product flow. Magnetic separators cause practically no product loss and are suitable for removal of regularly occurring and larger quantities of metal contamination.

A metal detector is mainly used as a means of inspection for sporadically occurring metal contamination. A metal detector only detects. If you want to remove the metal particle, the production line has to be stopped, or a rejection mechanism should eject the metal particle – resulting in much product loss.

Cylindrical magnets

You find cylindrical magnets in our bullet magnets, magnetic drum separators, magnetic head pulleys and eddy current non-ferrous separators. With the exception of the bullet magnet, these magnets dispose of the captured metal particles directly and continuously. They are therefore capable of separating or sorting large quantities of metal contaminations.

Magnetic drum separators

Bullet magnets and magnetic drum separators can be found in the solutions group "Magnetic filtering". Extra robust types of magnetic drum separators, magnetic head pulleys and eddy current separators can be found in the solutions group Magnetic recycling & sorting.