Metal separators - Magnetic bars & grids Cleanflow magnets Magnetic filters for pressure lines Bullet magnets Plate & block magnets Chute magnets Drum separators

Metal detectors - Suspension magnets, Magnetic filters, Gridmagnets, Magnetic head pulleys, Magnetic drum separators, Overband magnets, Eddy current separators

Magnets - Neodymium magnets - NdFeB Ferrite magnets Samarium cobalt magnets - SmCo AlNiCo magnets Plastic-bonded neodymium magnets

Magnets deferrization - Magnetic separators filter and remove metal contaminants from your product flow. They increase product quality and prevent damage to your production l

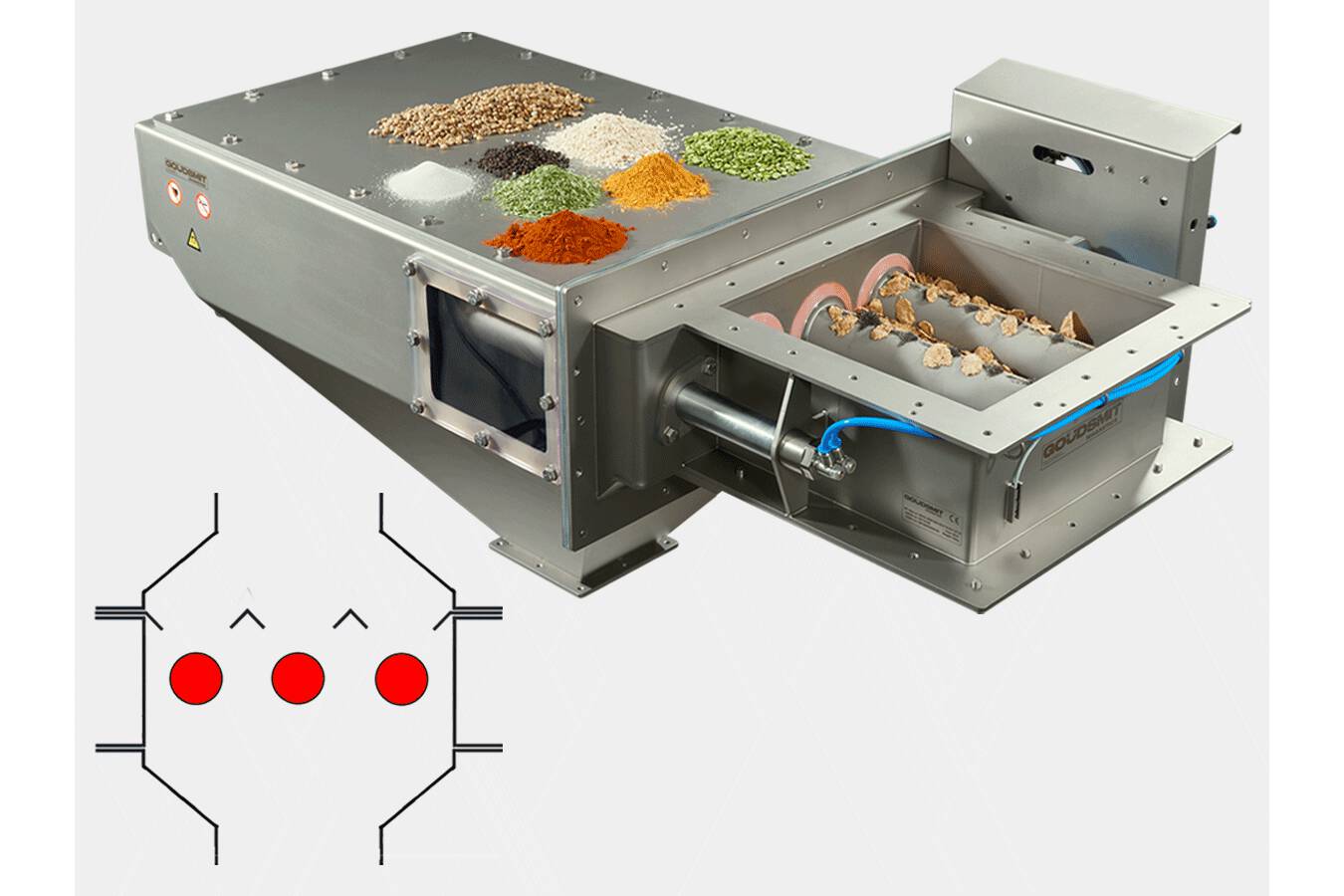

Chute magnets - Chute magnets are very robust and process large capacities of bulk materials.

Bullet magnets - Bullet magnets are exactly in the center of the product and filter medium to large ferrous contaminants from high-capacity coarse bulk materials

Overband magnets - Overband magnets remove ferrous particles from raw materials and carry them away automatically and contiuously

Magnetic drum separators - For automatic continuous removal of ferrous and even weakly magnetic contaminants.

Plate- and blockmagnets - They are therefore suitable for filtering medium to large ferrous particles from your raw material flows.