Load cells for quantity measurement in glass processing

Weighing technology of MTS MessTechnik Sauerland GmbH ensures continuous supply of glass for the downstream processing plant Load cell for quantity measurement in glass processing

Glass can be recycled an unlimited number of times - without any loss of quality. Hardly any other raw material can do this. The recycling cycle consists of the following steps: collecting glass, transporting it, processing it, melting it down and forming it into new glass products.

The reprocessing process itself is very complex. In order not to lose sight of the effort required for reprocessing, it is essential to record the mass flows in the reprocessing process.

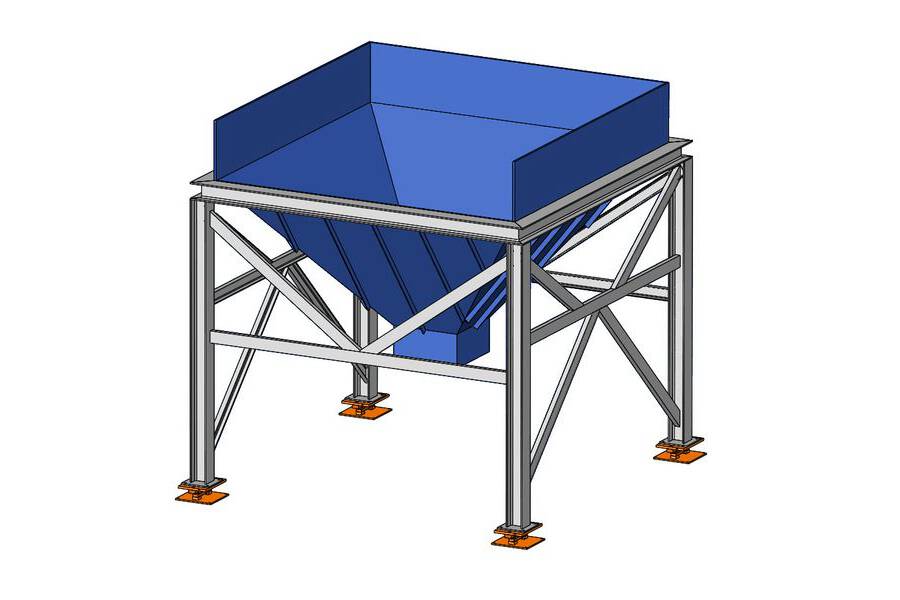

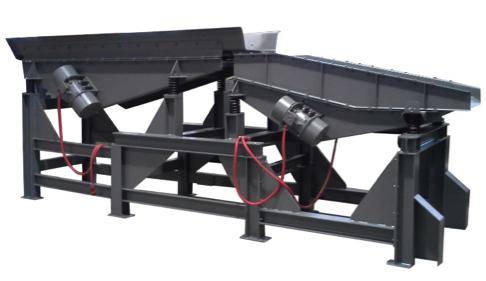

With this in mind, the family-run recycling company Reiling Glas Recycling GmbH & Co. KG from Marienfeld turned to MTS MessTechnik Sauerland GmbH. The task was to record the input quantity of ”hollow glass” in the charging bunker in order to ensure a continuous supply of material for the downstream processing plant. And this, if possible, without any additional effort in the process sequence.

Weighing technology from the high-load range

The