Environmental Technology Customer Day at Lake Constance

In October, the southern German office and environmental technology manufacturer HSM GmbH + Co. KG invited customers to its plants Frickingen and Salem. Around 100 guests travelled to Lake Constance from all over Germany, Austria, Switzerland, Italy, the Czech Republic, Serbia, Estonia, Russia, Thailand, and many other countries, to take part in days packed with information.

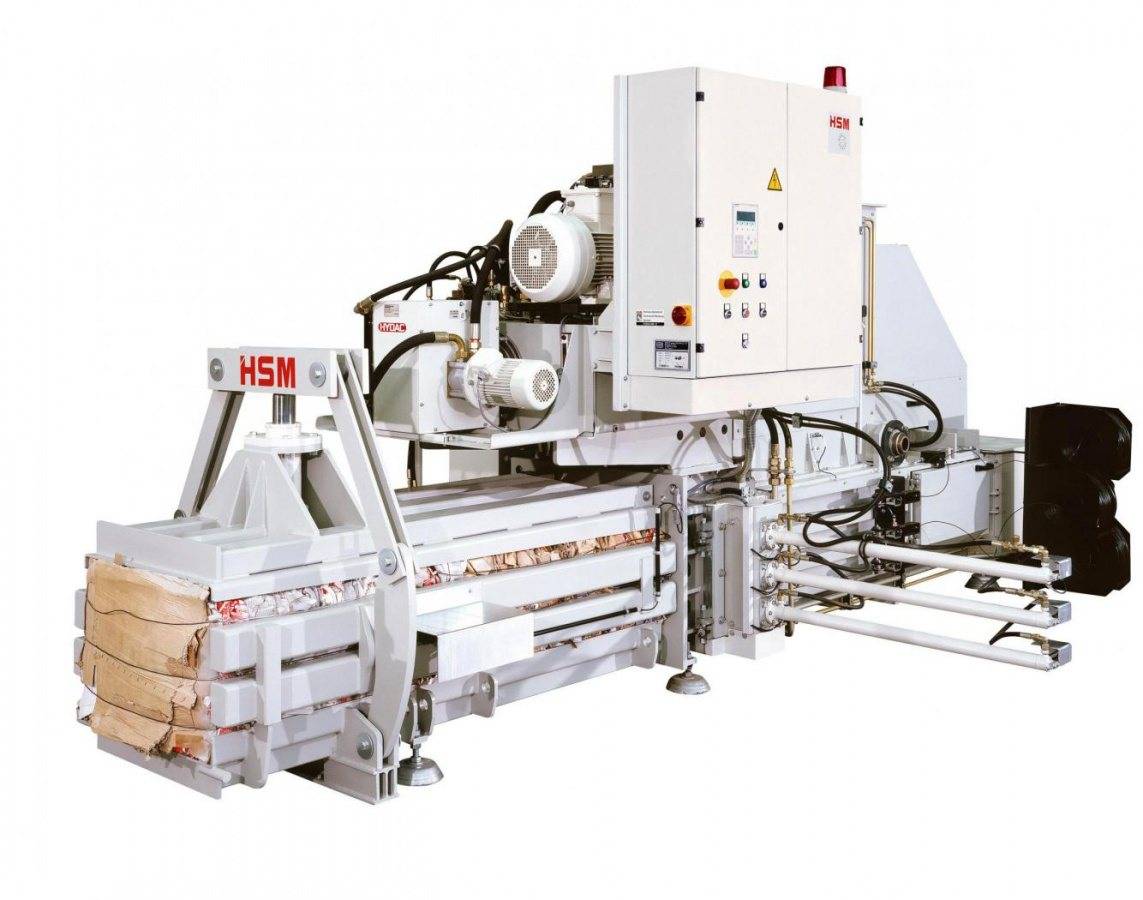

At the headquarters in Frickingen, Hermann Schwelling, managing director and company founder, welcomed the guests, who were mostly specialists from the waste disposal sector, as well as HSM sales partners from all over the world. HSM operates in the strategic business areas of office technology and environmental technology with around 900 employees worldwide. Hermann Schwelling showed the visitors impressive figures from the area of production: HSM produces over 3,000 bale presses a year with a pressing force of up to 150 tons. HSM produces over 400 horizontal ball presses annually, as well as around