Baling presses for every application

HSM presents as a competent partner at the IFAT trade fair in Munich From 15 - 18 May, HSM GmbH + Co. KG, the south German manufacturer of baling presses, PET solutions and document shredders, will present its extensive range of products at IFAT, the world’s leading trade fair for water, sewage, waste and raw materials management, in Munich in Hall B5, booth 251/350.

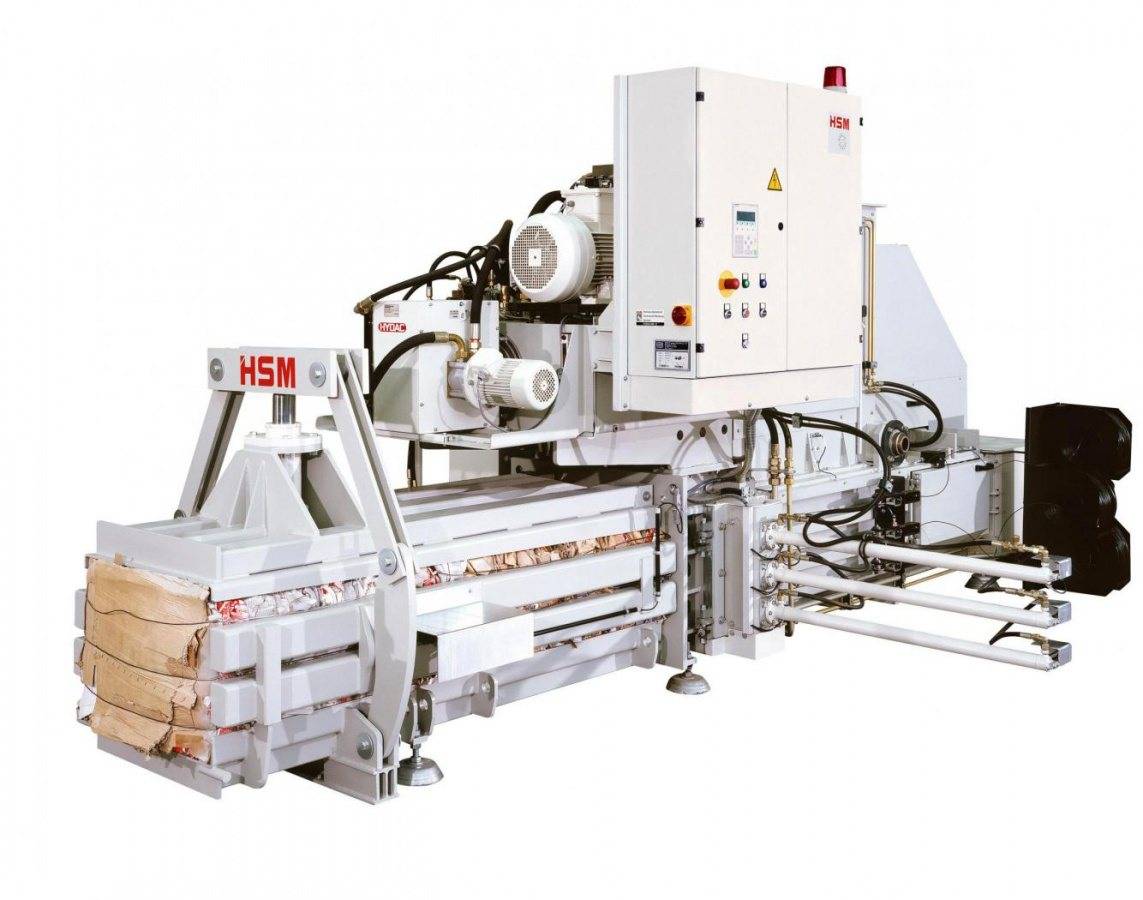

The exhibition will include the latest horizontal baling press, HSM HL 7009 with a press force of 700 kN, among other things. The compact horizontal baling press is the economic and space-saving disposal solution for chain stores and retailers, and it easily compresses cardboard and foil. With a cross-section of 1100 x 1100 mm and a bale length of 1200 mm, the bales weight up to 600 kg. In this way, the four-fold horizontally strapped bales achieve optimum truck utilisation. The integrated hydraulic lifting and tilting device means a significant reduction in personnel commitment during the compaction of recyclables. Thanks to the large-sized filler opening, even bulky