NEUE HERBOLD is a German manufacturer of size reduction machines / recycling systems for recyclable materials. Our mainfield is the preparation of plastics but also other recyclable materials such as electrical waste, cable, wooden pallets ,. , , ,

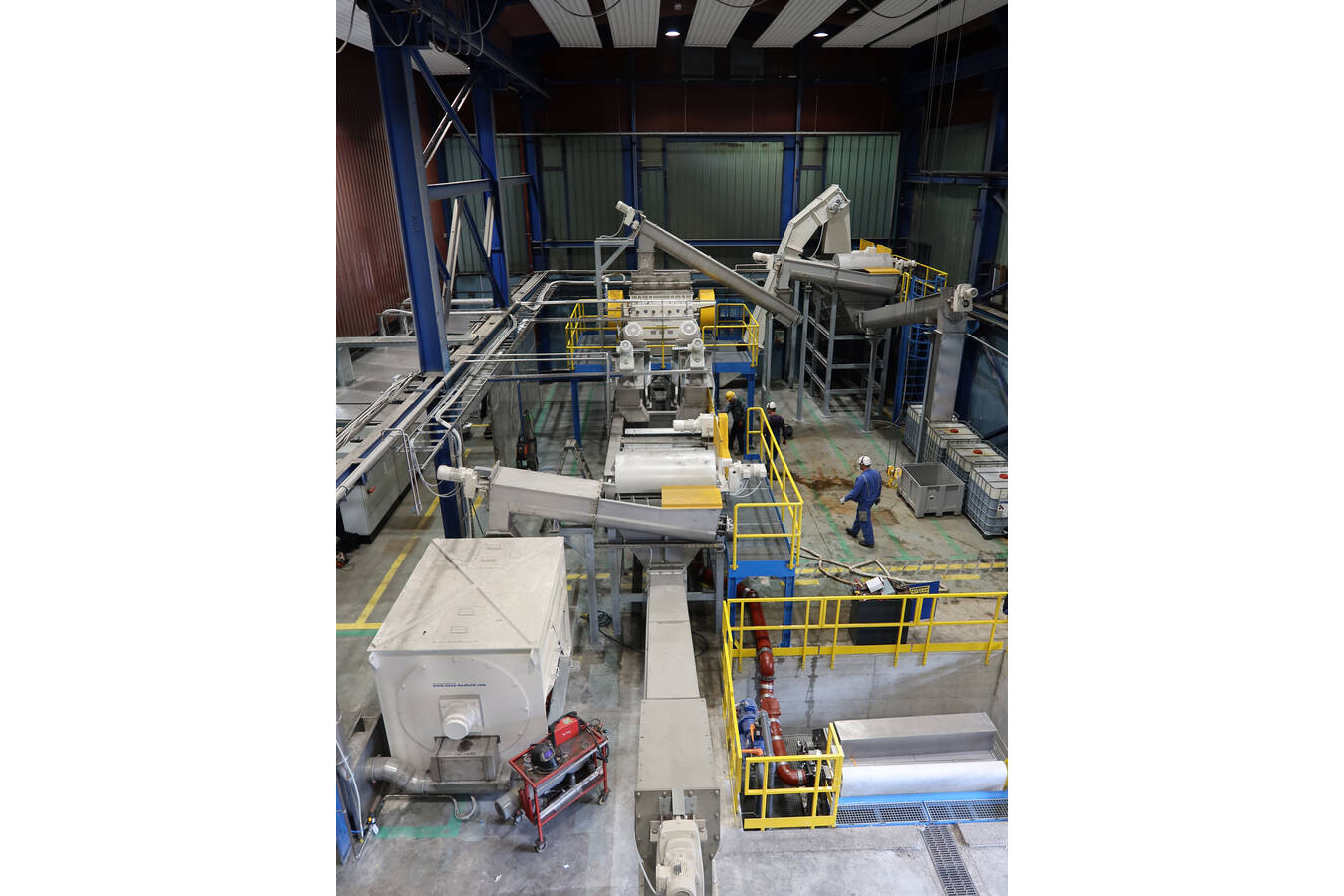

Our production program here includes the full range of shredding technology (Shredder, Bale Breaker, Screw Shredder, Pipe Shredders, Guillotines, cutting mills, pipe mills, profile mills, hammer mills, pulverizers, impact disc mills) to the Processing Technology

in the wet area. Here, to be recycled plastics are prepared after size reduction by adding

water (or even partial liquor) in our washing plants. Here are among other complete especially compiled for the customer demand systems available or

also the corresponding individual units or as a supplement to optimize existing customer plants. (such. ss separation tank (float / sink tank), Friction washers, intensive washer, drying centrifuge, thermal dryers, dewatering screws, ...)

Also we provide aggregates for the recycling of plastic waste and the separation technology for mixed Materials.

Conveyors for feeding (conveyor belts, screw conveyors) of the feed material - and removal of the crushed material.

We are continually examining in our technical guide our conceptions and when necessary adjustments.

We offer our customers the opportunity to experience the capabilities of NEUE HERBOLD in our technical center.

Finally, we can offer our customers a quality service and are also capable of your existing machinery and equipment to care for properly and to incorporate new ideas

Products, services

plastic size reduction - Cutting Mill, Granulator, weg-granulator, PET granulation, Cutting mill with force feeding system

shredder - one shaft shredder, 4 shaft shredder, pipe shredder

recycling plants - Plastic recycling lines, plastic recycling plant, separation tank, friction washer, dryer

Granulators - Plastic granulators, wet granulators, cutting mills, knive mills

Categories

Crush, break - Crushers, mills -

Hammer millsCrush, break - Crushers, mills -

Impact millsCrush, break - Crushers, mills -

Knife cuttersSeparation, sieving, filtering - Separation -

Plastic separatorsApplications - Recycling of materials group 3 -

Recycling of plastic bottlesApplications - Recycling of materials group 3 -

Recycling of plasticsApplications - Recycling of materials group 4 -

Recycling of polyethyleneCrush, break - Crushers, mills -

Single shaft shredderEnvironment - Cleaning -

Wash installationsCrush, break - Crushers, mills -

Zigzag classifiers