Crushing, disposal and compaction of PET bottles

By using the HSM PET Crusher 1049 SA, the volume of PET bottles can be reduced to around 25 or 30 percent of their original size. 500 billion PET bottles are produced each year around the world. The production of 1 kg of PET bottles requires 1.9 kg of crude oil. In the light of this figure, the recycling of used PET bottles is becoming more relevant than ever. More than 90% of all PET bottles produced are single-use bottles. Because PET is fully recyclable, PET is a key element in the reusable material cycle for the production, for instance, of fibres for textile production, film, packaging tapes and even furniture. HSM rose to this challenge some years ago and has been using its expertise in the environmental industry to develop customised solutions for the effective recycling of PET bottles.

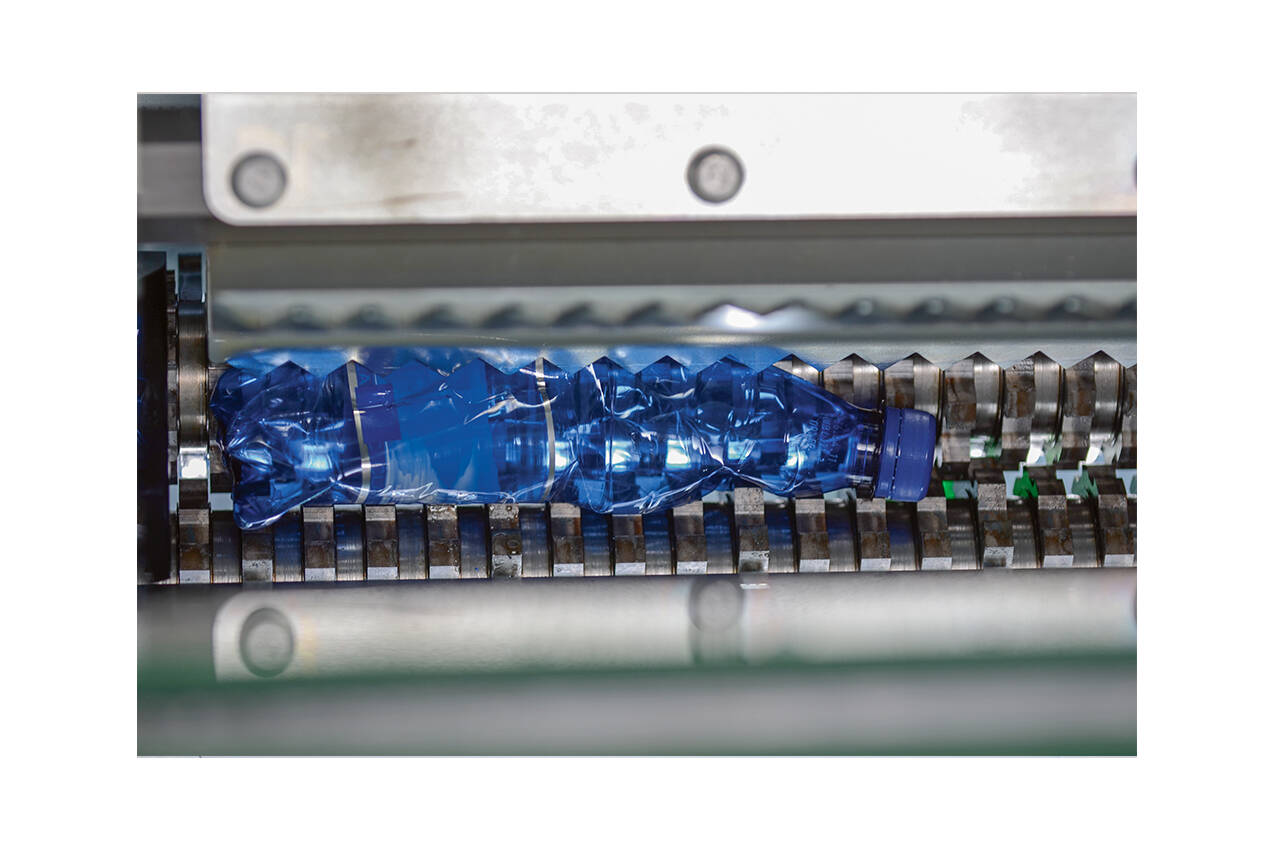

The HSM PET Crusher is an effective system for compacting PET bottles and cans to around 1/3 or even 1/4 of their original volume. The cutting units can also be used in combination with deposit return machines.

The sophisticated technology of the HSM PET Crusher

The crusher rollers are made from a