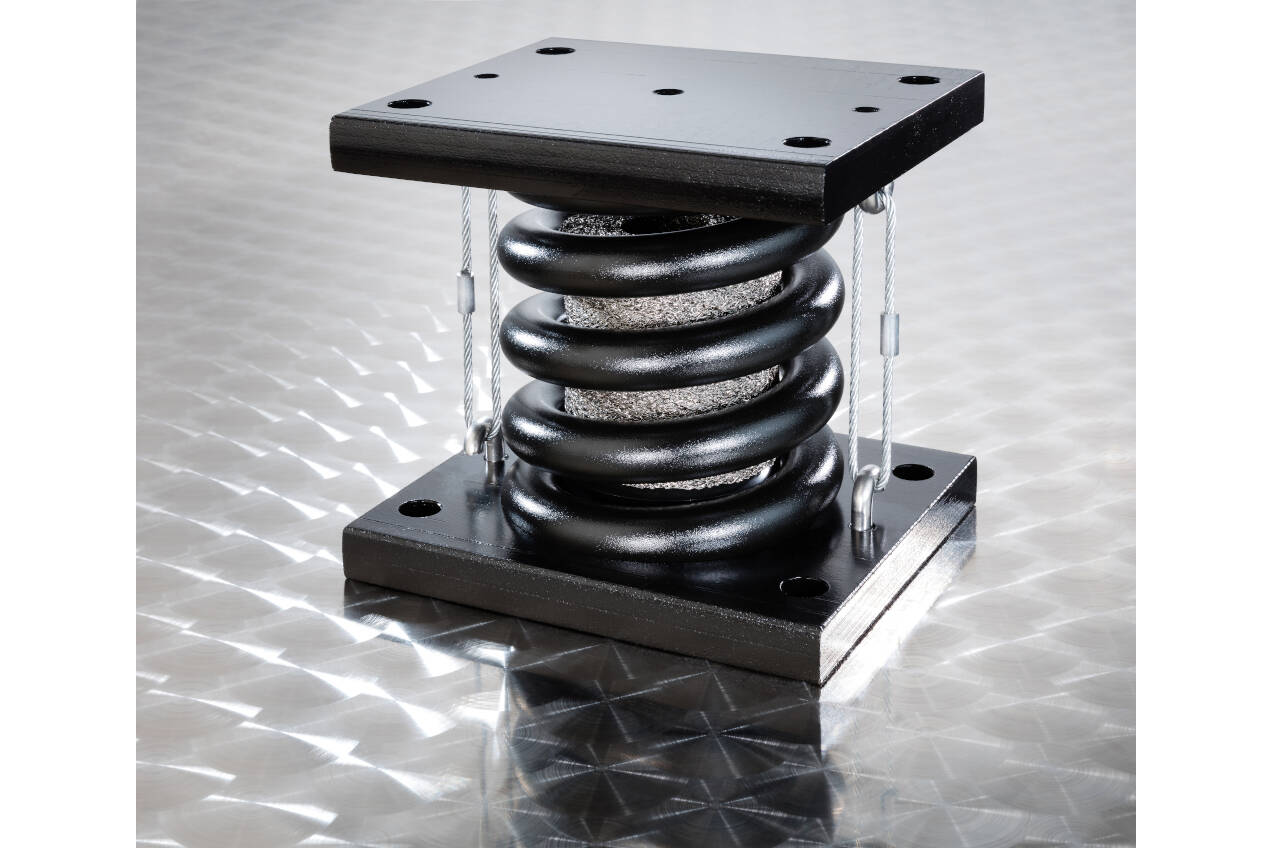

Wire mesh vibration dampers as an alternative to the standard

Almost everyone is familiar with vibration dampers made of elastomers. When conditions get tougher, rubber-based vibration isolators reach their limits. Production in a multi-phase process, partly by hand

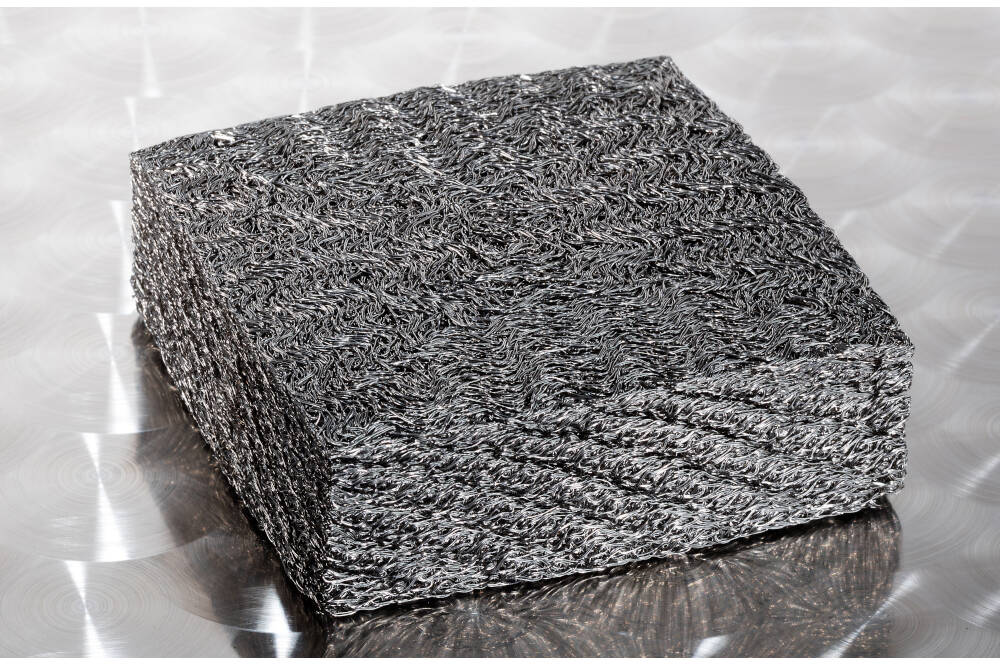

The basis or the main element of every vibration damper is the damping pad made of stainless-steel wire. This is produced in a multi-stage process. First and foremost is the knitting of several stainless-steel wires into a stocking. This stocking is then rolled to create a mat. While these processes are automated, the next step is manual. The existing mat is pulled over a mandrel and brought into its mostly cylindrical shape. At the end of production, this blank is pressed and spot-welded to create an elastic molded part. This is used as a damping pad.

Design parameters

An element is characterized by the same values that describe the corresponding geometric shape. For the cylindrical cushion, the outer diameter, inner diameter and height are required as a basis. For a rectangular cushioning element, the width, length and height. Other shapes can be adapted based on the geometry. The volume or density can be deduced