Lignin: Hosokawa Alpine and Lignopure announce collaboration

Hosokawa Alpine and Lignopure are working together to support Lignin manufacturers in the transformation and valorisation of this versatile raw material, optimizing lignin particles with target quality for various industries.

Augsburg machine and plant manufacturer Hosokawa Alpine will be collaborating with the Hamburg start-up Lignopure GmbH to boost the valorisation of the natural raw material lignin for industrial use. Together the two companies wish to develop innovative, tailor-made processes for the lignin market and provide their customers with individual solutions based on the quality of the initial material and its market potential. Lignopure’s experience in the field of lignin analytics, downstream processing/particle design and their application possibilities perfectly complements the profound knowledge that Hosokawa Alpine possesses about process development.

Lignin: natural raw material with versatile characteristics

Lignin is an organic phenolic polymer that occurs as a natural component in wood and other lignocelluloses. Its multifunctional protective properties play a huge role in the compressive strength and stability of the vegetable cellular structure. As a by-product, e.g. in the manufacturing of pulp and bioethanol in bio-refineries, lignin has barely been used industrially in higher-value applications to date, although it is available in large quantities. Hosokawa Alpine and Lignopure intend to contribute to the transformation towards a greener industry by joining their expertise in lignin transformation. ”Lignin is a natural, renewable raw material and can be used in the interest of the circular economy. Supporting companies in the preparation of lignin, therefore, tallies with our commitment to greater sustainability,” explains Dr. Antonio Fernández, President of Hosokawa Alpine AG. The natural properties of lignin are very attractive for a wide variety of applications, but making these applications a reality requires deep and interdisciplinary know-how. Lignin has shown great potential as a performance additive e.g. in (bio)compounds, foams, fibres and coatings and other materials - even as a multi-functional ingredient in natural cosmetics, where it replaces fossil or harmful materials.

Individual processes required

Like other natural raw materials, lignin is subject to certain quality fluctuations. In addition, lignin differs greatly depending on the raw material and extraction process. This means that there are no standard processing solutions for its transformation into a ready-to-use industrial additive. Instead, an in-depth understanding of the relevant application and its requirements is what is needed. For industrial use, lignin has to be provided in a consistent quality in powder or granular form, in order to ensure an equally consistent product quality. Excellent and tailored lignin particle properties are key to its performance in the vast majority of target applications. Lignopure and Hosokawa Alpine complement each other optimally, with their comprehensive knowledge of the material and its application options on the one hand, and the expertise in processing and preparation of powders and granulates on the other hand perfectly match each other.

Lignopure: material analysis, application potential and product design

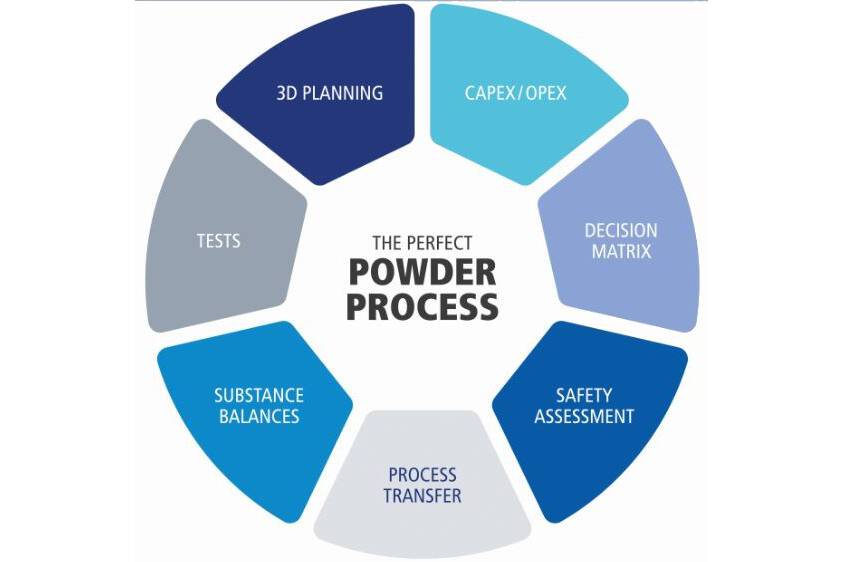

The team at Lignopure was already working with lignin and its positive effects in various application areas before the company was founded in 2019. One focal area is the use of lignin as a multifunctional ingredient for the cosmetic sector. With its product line LignoBaseTM, the startup has shown that with a thorough particle engineering lignin-based natural skincare ingredients can become a commercial reality. The natural protective functions of lignin are rendered accessible by optimising the lignin particles and maintaining the original properties of lignin for skincare products. Lignopure’s technology behind the cosmetic particles can, however, also be transferred very well to applications in the materials sector. Consequently, the company has set up its Lignin Application Services for customers from the pulp and bio-refineries sector, aiming to transfer their technology and know-how for industrial applications. The Hamburg-based company assesses the initial material and its potential but also the requirements for the intended end use. Based on this, the required lignin particle modification in order to obtain an optimal end product is determined. For the lignin manufacturers, also the provision of tailored powder prototypes for customer acquisition and application tests on a relevant scale is likewise essential. Hosokawa Alpine can subsequently build on this. ”Thanks to the thorough analyses carried out by Lignopure, we know where we have to apply our mechanical processing technologies in order to provide customers with lignin powder and granulate in the required quality,” explains Dr. Fernández.

Lignin is a very diverse material for which there is no standard solution. Therefore, Lignopure assesses the raw material as well as the requirements in the end application to achieve the optimal product and particle properties.

Hosokawa Alpine: process solutions from the pilot system to production

With the ARC MS compactor from Hosokawa Alpine, the lignin powder can be processed into a dust-free granulate or briquette with a constant, very high product quality.

In turn, Hosokawa Alpine has the required know-how and technologies to process lignin with the required properties as best as possible. From the initial tests in its technical centres in Augsburg and Leingarten via pilot plants and industrial scale-up: The mechanical engineering company develops a tailor-made process for customer requirements and subsequently delivers the systems for industrial roll-out. ”Hosokawa offers cutting-edge technology to valorize and transform materials, which complements our expertise in tailoring lignin quality to meet the market requirements. This collaboration will enable us to leverage our expertise in lignin valorization and with their advanced processing capabilities, creating new opportunities for lignin producers and end manufactures of biobased products. Together we are committed to bring lignin closer to the market, adding to a more sustainable future.” explains Joana Gil, founder and CEO of Lignopure contentedly.

With their application services, Hosokawa Alpine and Lignopure wish to jointly accompany lignin manufacturers on the path to market launch, from analysis of the material and identification of its application potential, joint stipulation and optimisation of its particle and product properties, prototyping and right-up to the roll-out of tailor-made process solutions on a pilot project or industrial scale.