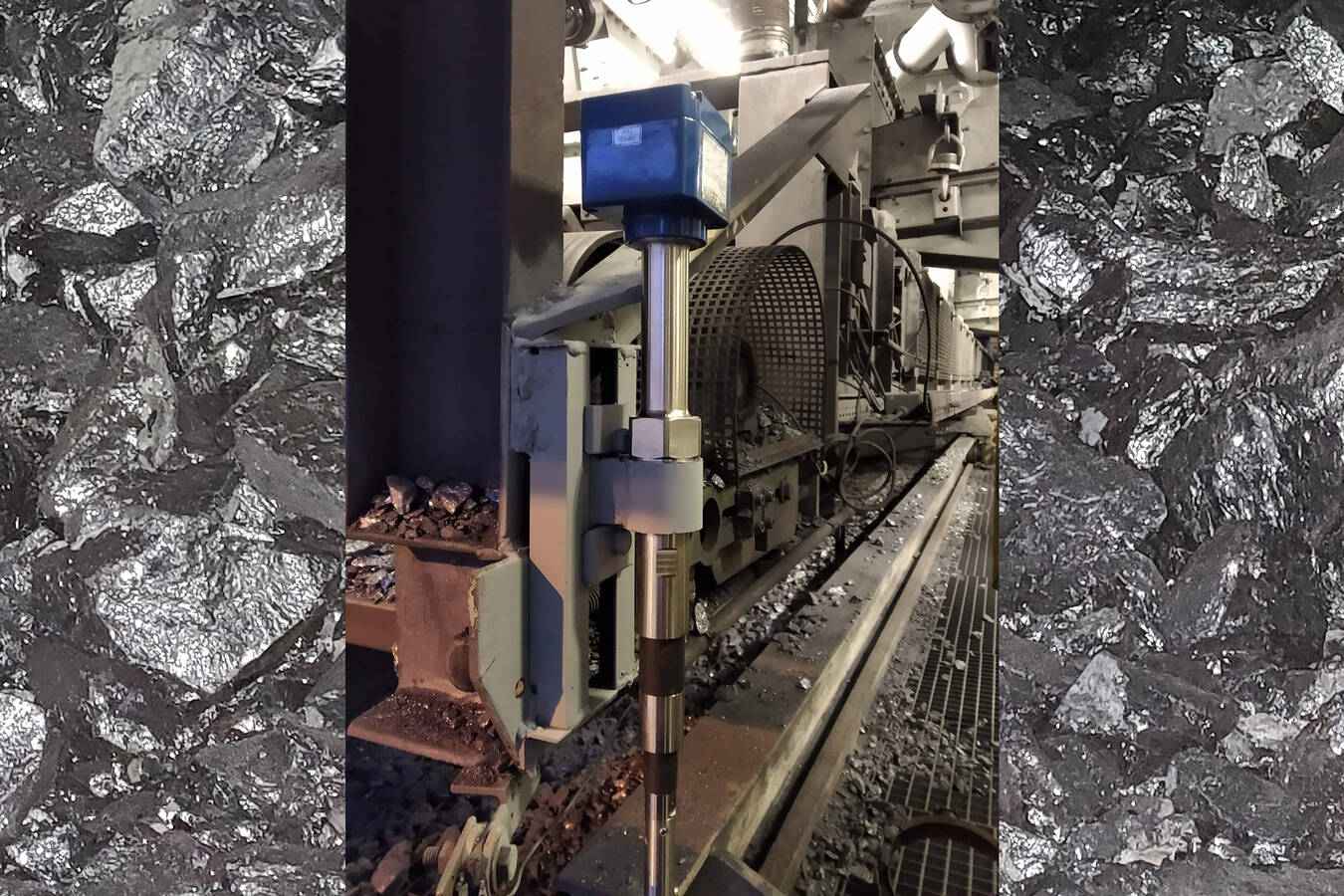

Resistant RF level limit switch with dust-proof design by UWT

Capacitance measurement technology RFnivo® 3000 for conveying process optimization for a silicon metal manufacturer A silicon metal production facility in Iceland was looking for a suitable level measurement technology to coordinate the filling of sea containers with silicate rock. Due to the very abrasive material, a heavy-duty capacitive probe should be used. With the project planning of a proven point level switch from UWT with the innovative RF technology, a compatible solution, which is robust and delivers reliable results, could be found.

Silicon metal is used in a variety of applications in the chemical industry, e.g. in the manufacture of siloxane and silicones, as well as in the production of high-strength aluminum alloys for the automotive industry. It is also often a primary raw material in the manufacture of photovoltaic modules. In the production processes of a manufacturer in Iceland, an above-average sustainability balance is strived for, which includes equipping its system with modern and efficient component technology. Therefore, the implementation of innovative