Quality pays off: 12 months of uninterrupted process operation

UWT’s rotary paddle level switch ensures a reliable process in peanut butter production: UWT’s RN6004 eliminates frequent sensor failures and reduces downtime and costs

One of the world’s largest peanut butter companies, with a production plant in Kentucky, was having issues with their level measurement sensors installed in the production area of their plant. To solve the problem, the Rotonivo® rotary paddle sensor was introduced, which significantly improved operational efficiency and reduced plant downtime. Once again, UWT has demonstrated its experience and commitment to providing innovative solutions to the industry.

Malfunctions and high costs

At their production plant in Kentucky, the peanut butter manufacturer had been dealing with constant problems with their measurement sensors. The rotary paddle sensors by another brand that they had previously installed had a very short life span, often failing within a day.

Eliminating high levels of downtime

The main problem that was causing the sensor to break down was salt and sugar build-up around the probe shaft, which the motor was unable to remove. At the same time, these materials were getting into the seals and bearings, causing the paddles to stop rotating. All of these sensor failures were causing extensive downtime and high replacement costs, which significantly affected the plant’s production capability.

In order to resolve the frequent production disruptions, the operator requested assistance from the UWT Level Control LLC team based in the USA and led by David Spratlin, Managing Director, to replace the sensors.

UWT measurement sensors you can count on

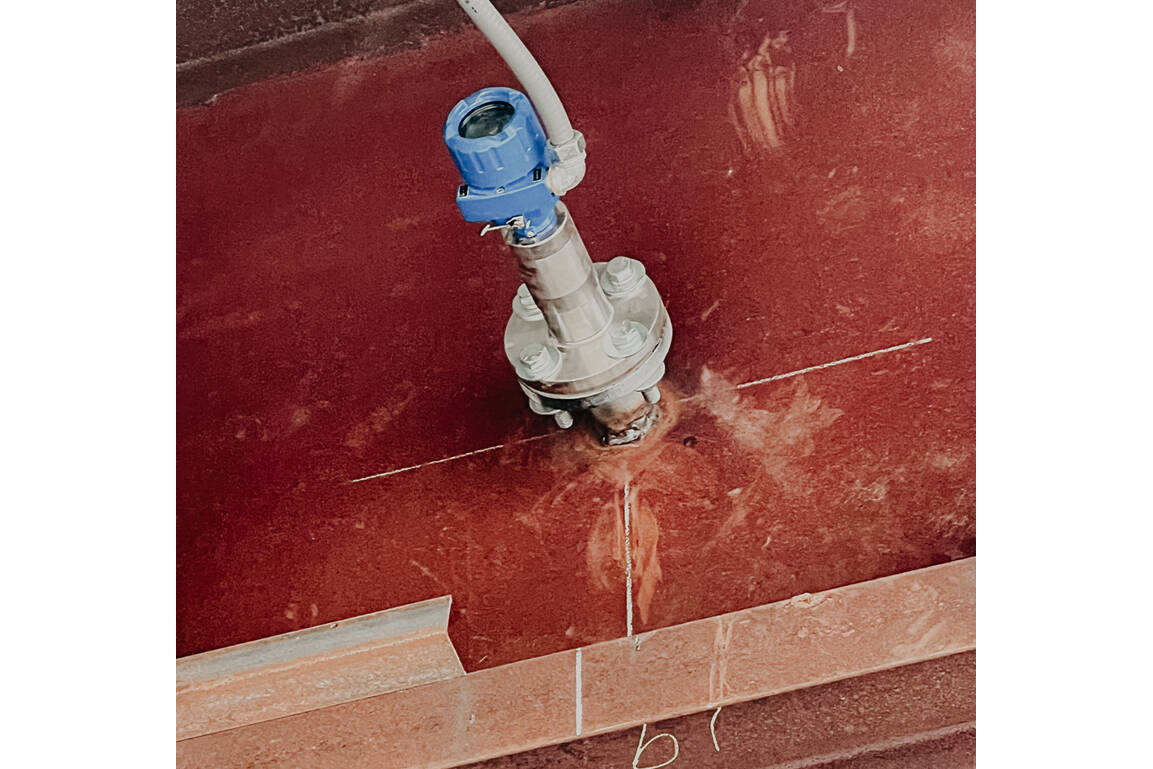

In response, UWT offered the Rotonivo® - 6004. The rotary paddle sensor with a reinforced shaft and double stainless-steel bearings ensures high durability when in contact with dense materials. Additionally, the double stainless-steel bearings prevent materials such as salt and sugar from wearing out the sensor seals and entering the electronics. This had been a common problem with the previously used sensors, which had led to their failure.

The UWT RN 6004 rotary paddle level switch is used in bulk solids processing plants as overfill protection and empty protection for storage and process containers. It can be configured as a full, demand and empty detector for process temperatures of up to +600 °C and a process overpressure of up to 10 bar and is mechanically very resilient. Thanks to the larger housing, the RN 6004 offers more space for wiring and is equipped with flameproof housings for use in the GasEx area. It is certified to SIL2 and meets the increased hygiene requirements in accordance with EHEDG guidelines.

One year of uninterrupted process operation

12 months on from installing the UWT Rotonivo® - 6004 paddle sensors, there has been a continuous and fault free process at this peanut butter production plant.

This is a significant improvement from the earlier situation where the other make of sensors had required frequent repairs, resulting in time-consuming and costly maintenance. The successful implementation of the RN 6004 at the Lexington (Kentucky) peanut butter plant underscores UWT’s commitment to providing reliable solutions tailored to customer needs, consistently exceeding expectations through innovation.

Maintenance-free solutions

As this case shows, UWT has once again proven that, as an expert in level measurement technology with an experienced team and enormous industry knowledge, it is a reliable, globally leading solution provider for the safe, durable and accurate detection of fill levels and limit levels in silo systems and material handling processes in a wide range of industries.

With product lines such as the Rotonivo® rotary paddle level switch, the Vibranivo® vibrating fork and the NivoBob® plumb bob sensor, UWT is rightly synonymous with the perfect measurement technology solution for almost any application.

UWT sensors are reliable, absolutely maintenance-free and work according to the ”install and forget” principle. They can be configured in a variety of ways and offer added value for different areas of application.