Shakers, vibrators, knockers – there are many solutions for free material flow in the bulk goods industry. Yet, finding the right one can sometimes feel more complicated than necessary. singold gerätetechnik gmbh, manufacturer of the world’s first and, therefore, original pneumatic knocker, has a simple but all the more effective approach: whenever a hand hammer can get the bulk material flowing again, the pneumatic knocker will do the same. However, it has significantly more power, requires no human effort and does not dent the silo.

The pneumatic knocker was first developed over 50 years ago by company founder Erwin Lüer, and to this day, singold’s pneumatic knockers remain the most powerful on the market. They operate only when needed, minimizing strain on weld seams that can otherwise fatigue under continuous vibration. By activating as required, the pneumatic knocker protects containers, reduces compressed air consumption, and lowers noise levels, contributing to a safer work environment.

Choice of different knocker sizes

Several factors should be considered when selecting a knocker. If the knocker’s force is too powerful, it risks damaging the silo, while a knocker that is too weak may be ineffective and wear out prematurely. Fortunately, choosing the right knocker is easy. On-site users, familiar with their systems’ needs, can usually rely on practical experience to identify the best pneumatic knocker. For those who need assistance – such as when working with new systems – the knowledgeable team at singold gerätetechnik gmbh is always available, offering guidance that respects the user’s expertise and hands-on experience.

A practical online tool is also available on the company’s website that simplifies the process of selecting the right pneumatic knocker. In just three steps, users can enter essential parameters and generate an automated inquiry. Key questions include: What temperatures will the knocker face? What are the silo’s diameter and sheet thickness? Are there special requirements for handling aggressive dust? Will the knocker operate in hygienic environments, such as food production? All these factors are relevant for selecting the right knocker and can be easily answered by users on-site. The design and number of knockers required can then be read intuitively from a clear, interactive diagram.

Innovative online configurator for selecting the right knocker

Knocker selection chart

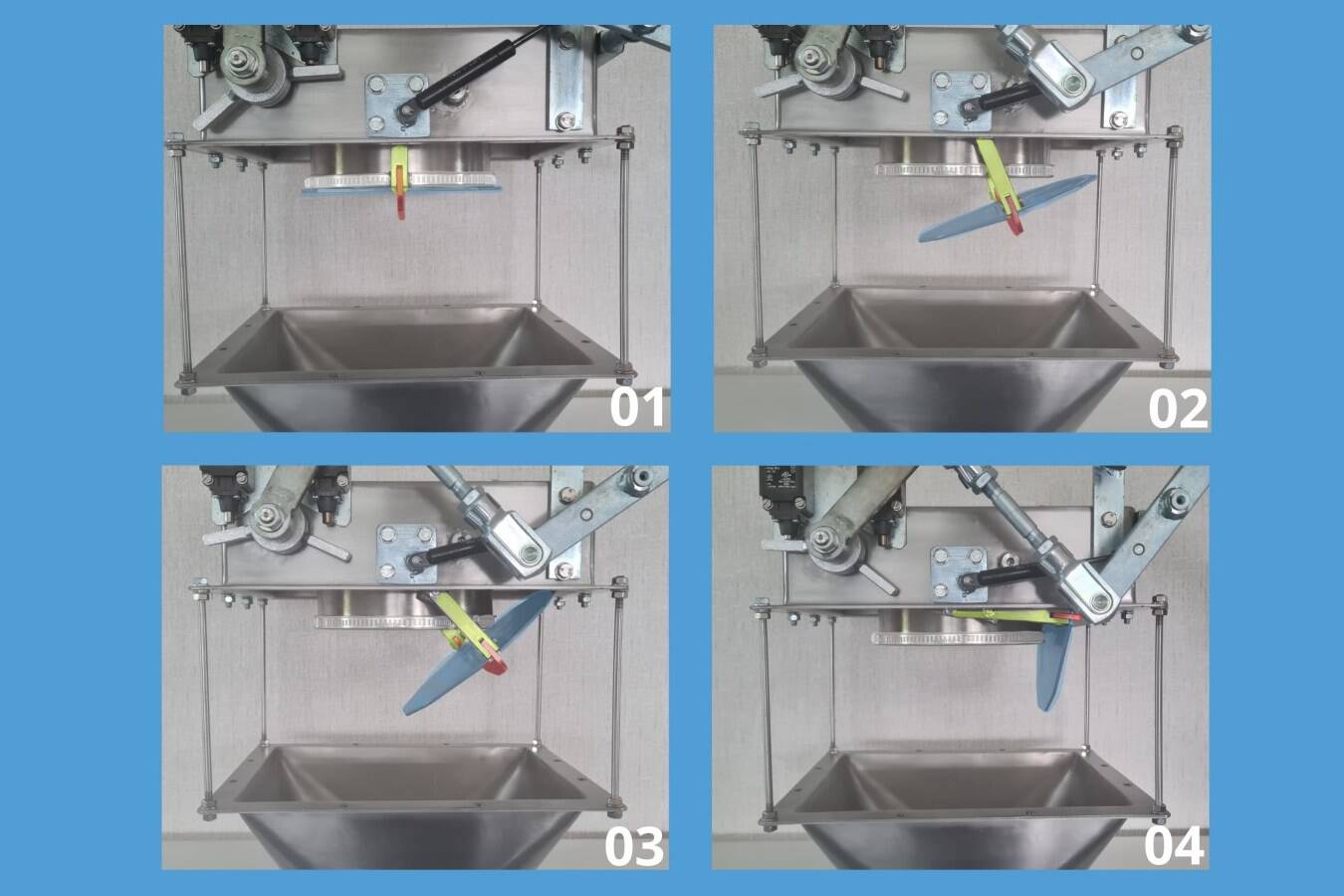

Not only is it easy to select the right pneumatic knocker, but the operation of the pneumatic knocker itself is almost ingeniously simple. The knocker releases stored compressed air energy in a quick burst, delivering a high-impact force that effectively addresses material flow issues like bridging, shafting, and residue buildup. Unlike high-speed vibrators or shakers with their gentler sinusoidal vibrations, the pneumatic knocker provides a precise elastic impact, free from residual force or imbalance. It’s typically operated electrically through a solenoid valve.

singold gerätetechnik gmbh offers a special solution for changing containers and slowly rotating drums as well as for hot walls: the distance knocker, in which the piston rod bridges a distance between the knocker and the container.

With ingeniously simple solutions, selected with the help of the practical experience of users on-site, bulk material flow is restored effortlessly.