POWER UP with smart Level Measurement Solutions

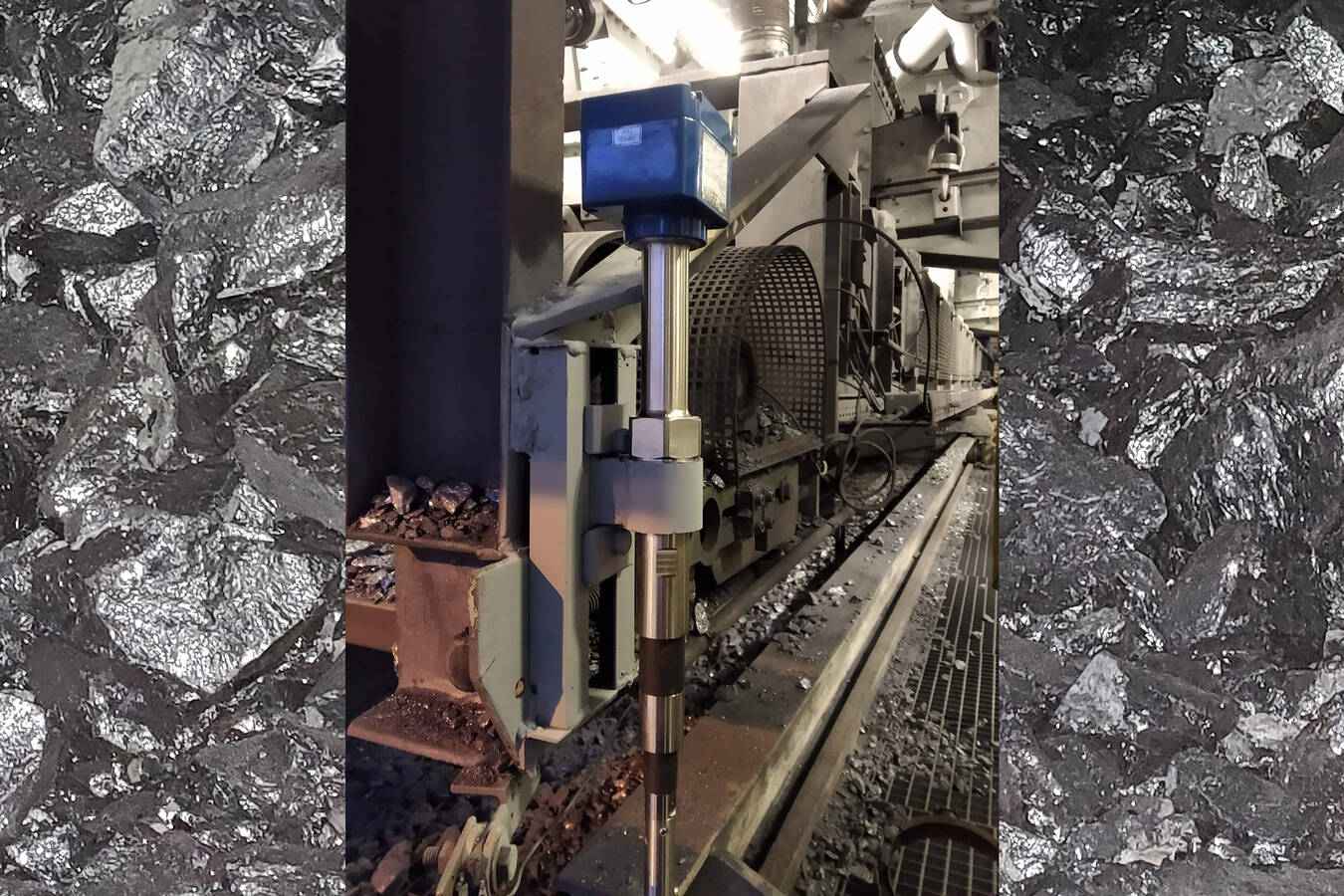

One of India’s largest energy suppliers equipped its coal handling processes with suitable level measurement technology to optimize the whole power plant flow. How to equip the lifeline of the power plant

In addition to natural gas, oil and nuclear power, coal is a major factor in the generation of electrical power. In line with the rapid development of the economy and of technology we have a continuously growing demand for electricity as mankind invents computers, intelligent home appliances, electric cars, intelligent robots and many more products that use electricity. Still rising consumption e.g. in China, India and the United States could bring global coal-fired power demand to a new all-time high. The requirements for electric power equipment are increasing: the need for them to be safe and reliable, with high availability, easy to install, no leakage, maintenance-free and to meet the requirements for environmental protection.

End of last year a big coal-fired power plant, located in Kharagpur, West Bengal, was looking for uncomplicated, high-performing and absolutely reliable measurement technology at an affordable