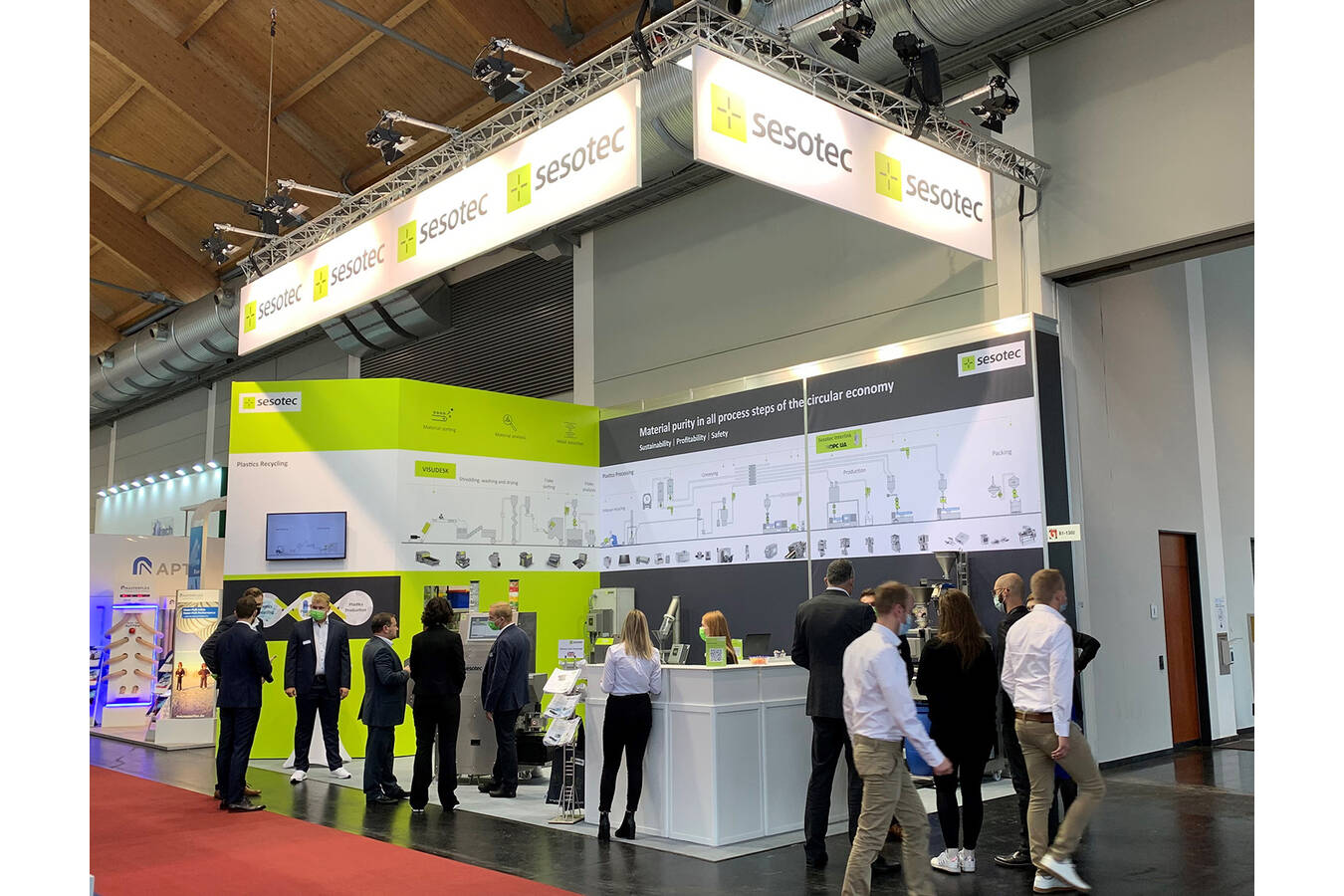

A strong showing for Sesotec at Fakuma 2021

Innovations for the circular economy: sustainable, environmentally friendly, and profitable Schönberg, November 2021

From October 12 to 16, 2021, the 27th Fakuma International Trade Fair for Plastics Processing took place in Friedrichshafen, Germany. In terms of content, this year’s Fakuma was centered on the topics of the circular economy, sustainability, and digitalization.

Under the motto “Material purity in all process steps of the circular economy,” Sesotec presented technologies and services that help plastics manufacturers, processors, and recyclers achieve circularity and efficiency in their production. Trade show highlights included the FLAKE SCAN material analysis system and the debut appearance of the mobile RE-SORT metal separation unit.

Being the first major plastics industry convention since the beginning of the pandemic, this year’s Fakuma attracted fewer visitors than in previous years. However, the Sesotec booth saw more than 300 visitors – many more than expected.

“We are back, and stronger than ever.” said Dietmar