Sesotec at Fakuma trade fair 2023: ”Economy meets Ecology“

Intelligent technologies and services for an effective and profitable circular economy, Fakuma trade fair in Friedrichshafen, Germany, from October 17 to 21, booth 1301 in hall B1. Schönberg, September 2023

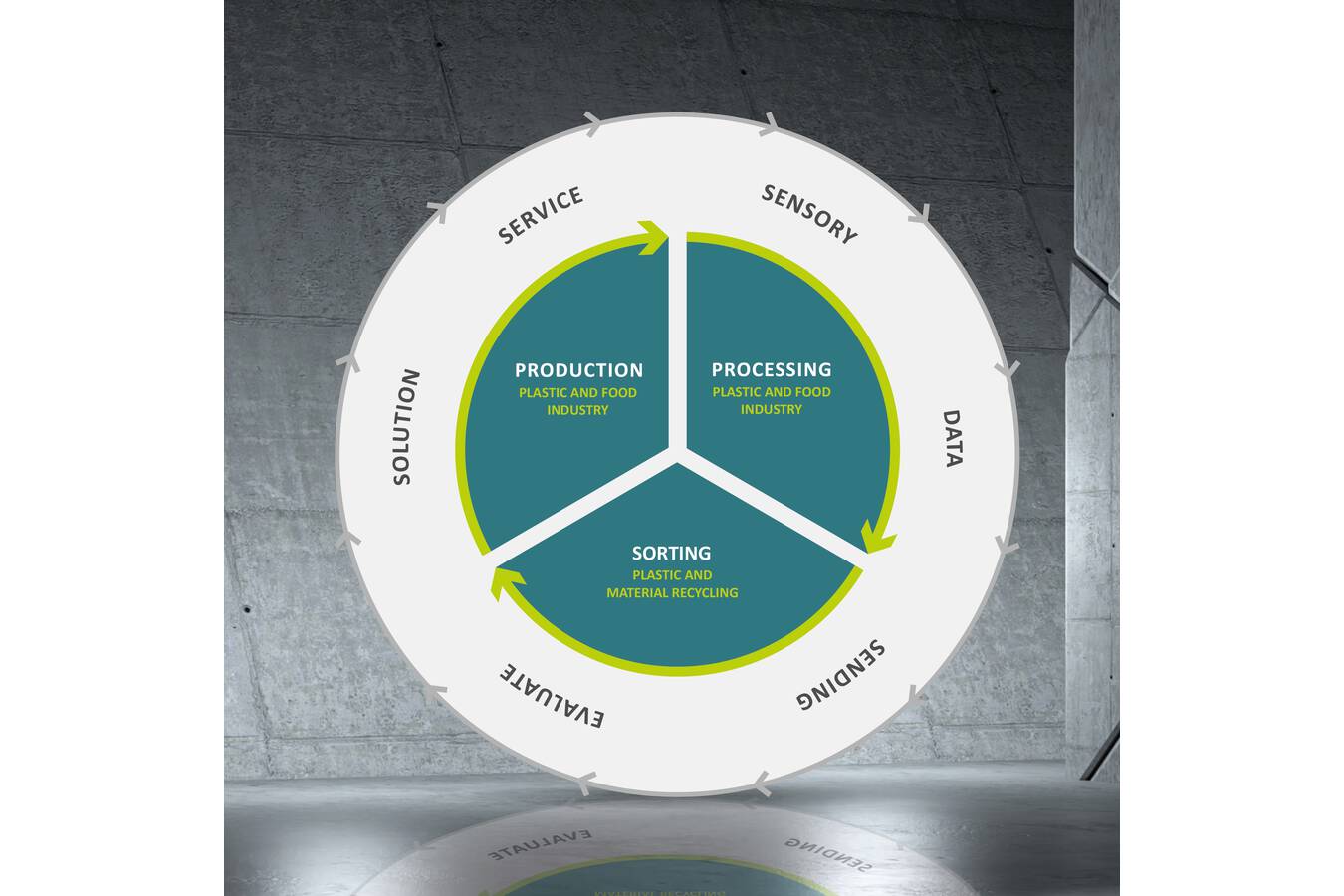

Sesotec GmbH, a leading manufacturer of metal detection, sorting and analysis systems, will be present at the Fakuma trade fair in Friedrichshafen, Germany, from October 17 to 21. Under the motto ”Economy meets Ecology,” Sesotec will demonstrate how intelligent technologies and sustainable business go hand in hand. Visitors can experience Sesotec’s innovative equipment and service solutions at booth 1301 in hall B1.

Premiere: PRE-SORT sorting platform

The major highlight of the trade show appearance is the premiere of the PRE-SORT sorting platform. This platform represents a considerable advance in the plastics and recycling industry and promises to redefine precision, efficiency and sustainability in the industry. With PRE-SORT, the components VARISORT COMPACT sorter, dedusting, material conveying and central control are combined on one platform. Depending on the requirements, plastic regrinds can be sorted according to colors,