AST Group Uses Lindner Plastics Recycling Technology

Circular Economy in the Spotlight: AST Group Uses Lindner Plastics

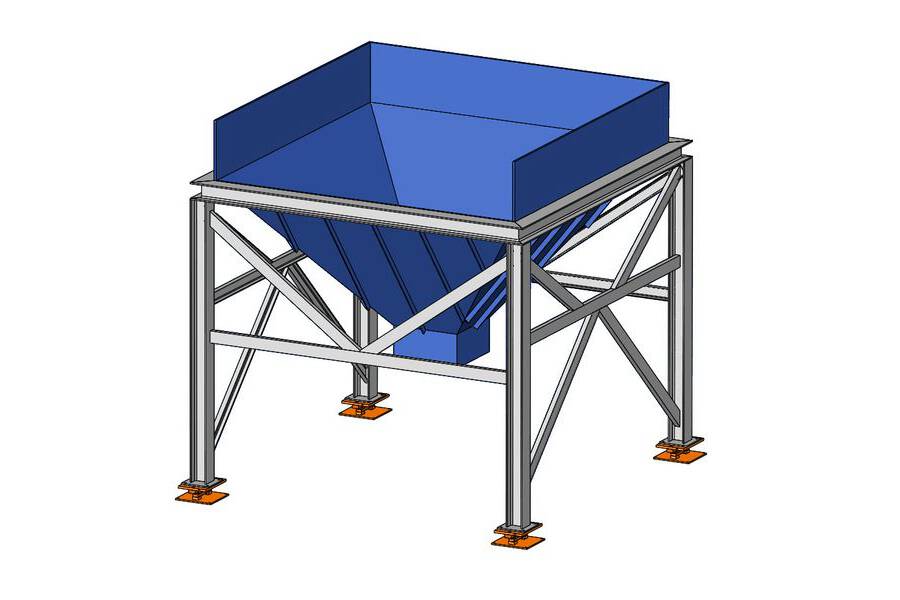

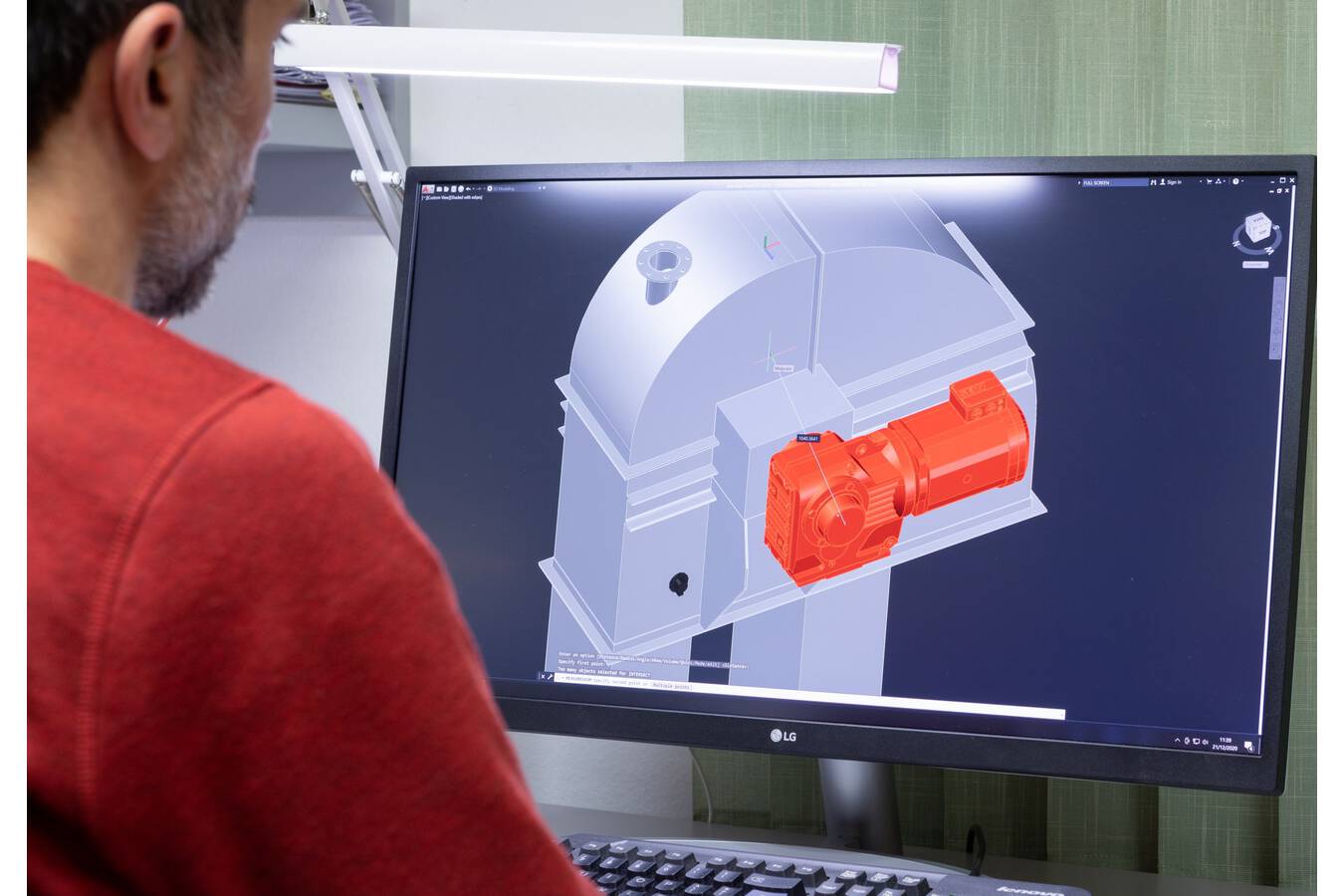

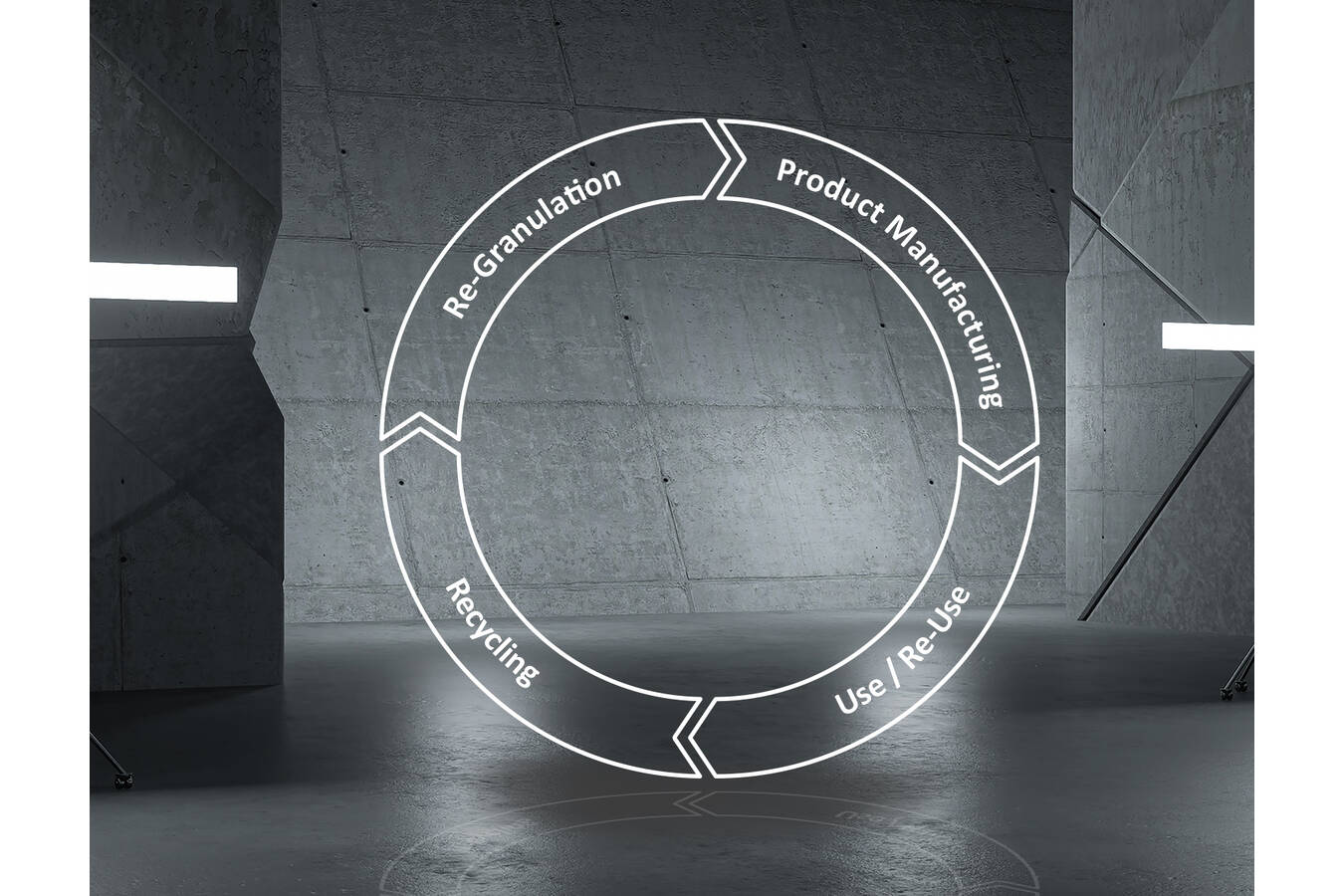

Recycling Technology to Close the Loop Since 2018, the AST Group, producer of HDPE plastic containers and drums, has been committed to cleaning and reconditioning used containers to ensure a longer service life for its products and greater sustainability in the production process. Since 2021, the loop has been closed by another piece – a plastics recycling facility (PRF) from Lindner has been processing post-consumer containers, which are then used to produce new drums and containers. As these products are also destined for the hazardous and foods industries, high-quality recyclate is crucial as are optimally coordinated recycling processes.

Managing our environment responsibly

Circular economy, the Green Deal, recycling quotas, resource conservation, energy efficiency, sustainability – these are the buzzwords we hear each and every day, especially in the recycling industry. After all, our industry is essentially about responsibly managing our environment and its resources as well as the associated