Turning Waste into Raw Materials: 30 Years of Krall Kunststoff-Recycl

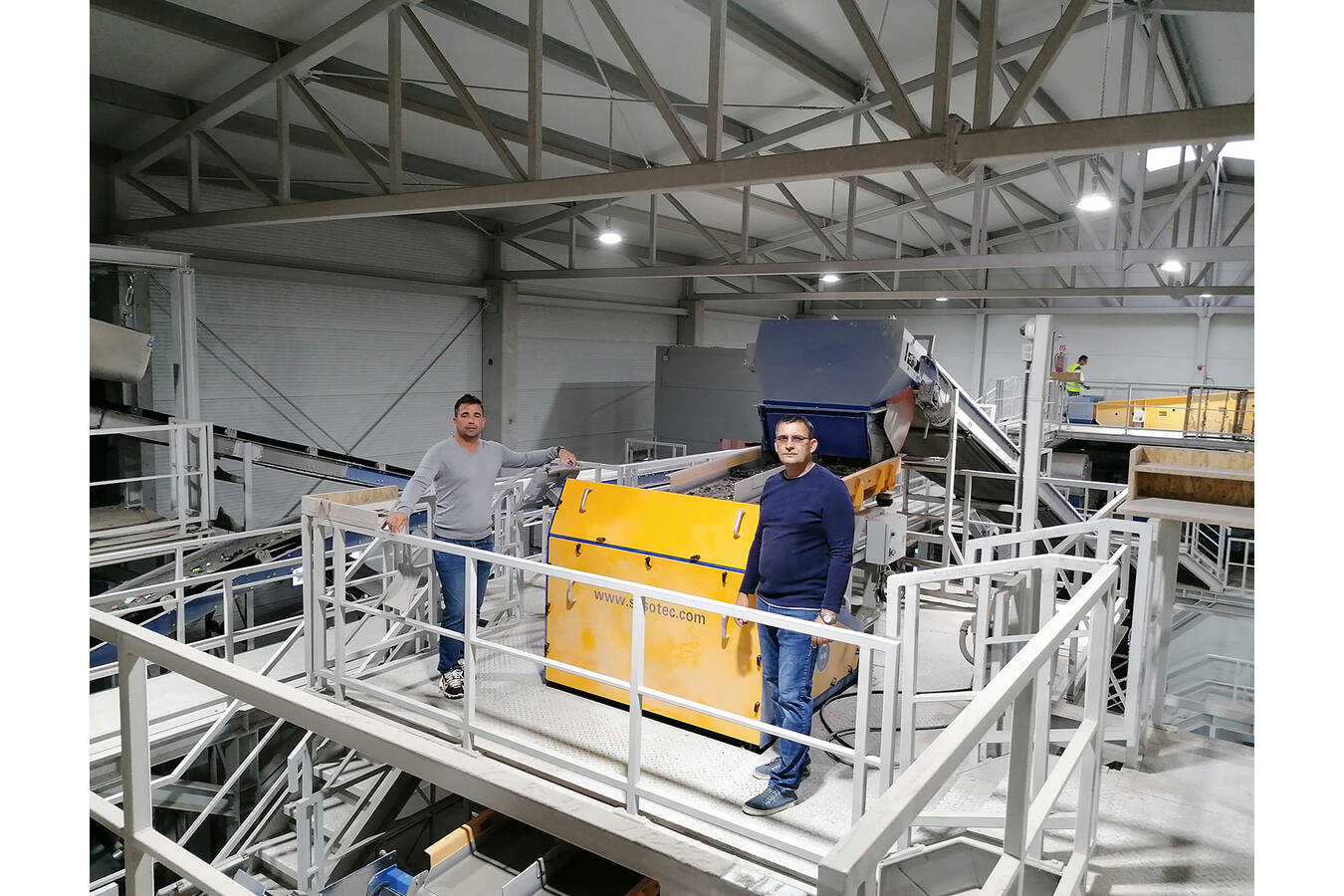

For three decades, sustainability has been the focus of the family-owned company Krall Kunststoff-Recycling in Elsenfeld am Main. Krall’s history began with a small plan t in early 1992, when “recycling” still was almost unheard of in public. Manufacturers and processors were offered the takeover of plastic residues for subsequent type-sorting and grinding. From the very beginning, executive director Markus Krall focussed on transparent plastic materials, mainly polycarbonate and PMMA, which constitute the core business still today. Further key aspects are engineering plastics and the recycling of CDs.

Today, the company comprises six workshops with a total floor area of 12,000 square meters. With about 40 employees, two shredding machines, and 10 chopping mills, the company will reprocess some 8,000 tonnes of plastic materials in the anniversary year, consequently working with environmentally friendly solar power. The type-sorted regrinds from Krall Kunststoff-Recycling are raw materials worldwide sought-for by processors who gladly return them into the materials cycle – for the direct