Level sensor VEGAPULS 6X -Security first at VEGA

The VEGAPULS 6X radar sensor is the world’s first level sensor with built-in cyber security features, in compliance with Industrial Cyber Security Standard IEC 62443-4-2. VEGA, the Black Forest manufacturer of level, switching and pressure instrumentation, is on a security mission. In January 2023, it delivered to its customers what is unquestionably the world’s first level sensor with built-in cyber security features. With this new development VEGA wants to send a strong message, namely, that it recognizes the increasing threat of cyber criminality in industry and is taking action to combat it.

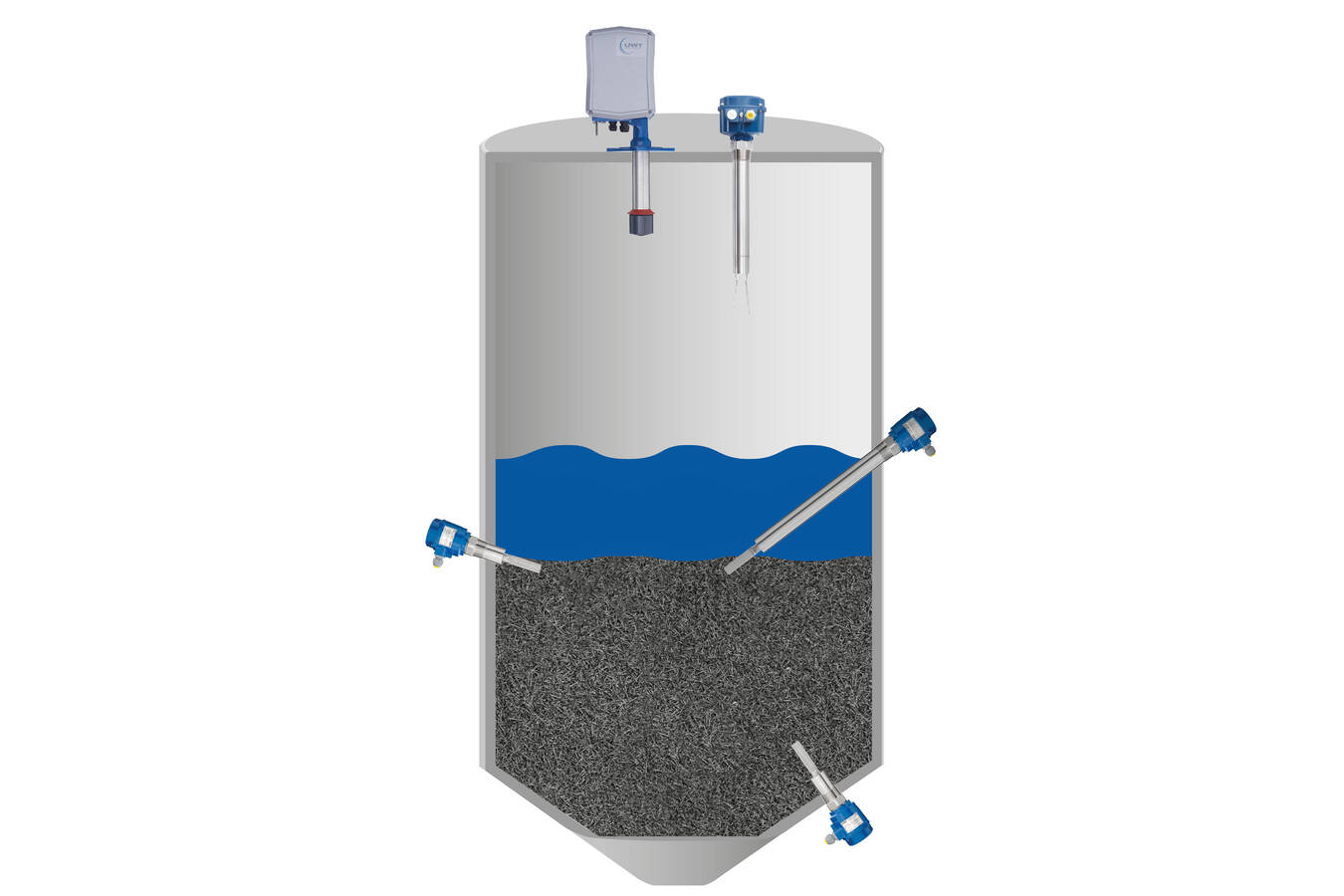

From the outside, you wouldn’t see anything different or unusual: The VEGAPULS 6X radar sensor, together with its documentation, fits perfectly into its tailor-made carton which, at the end of the packaging line, gets its shipping label. Address: A chemical company in northern Hesse, Germany. But what the customer receives is something quite different from all the other level sensors previously available in the market. For the first time ever, this sensor comes with cyber protection as an integral component. It was developed in compliance