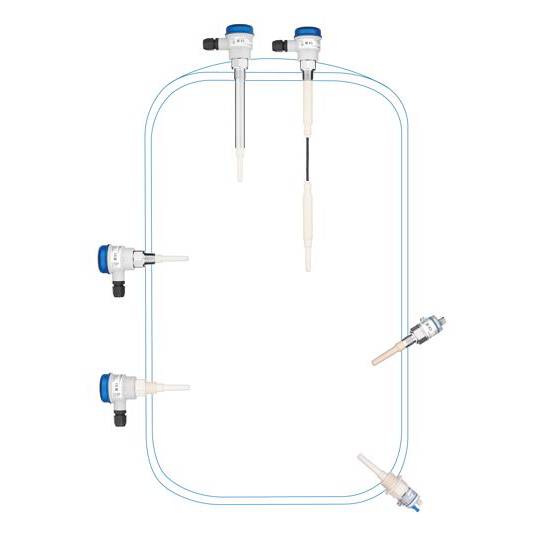

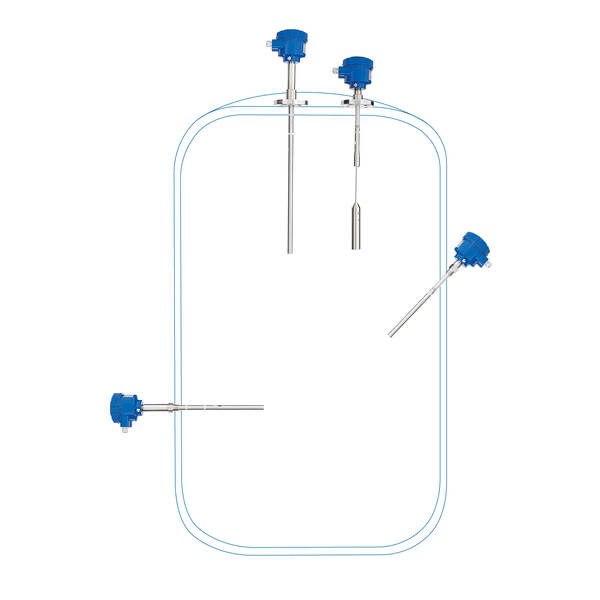

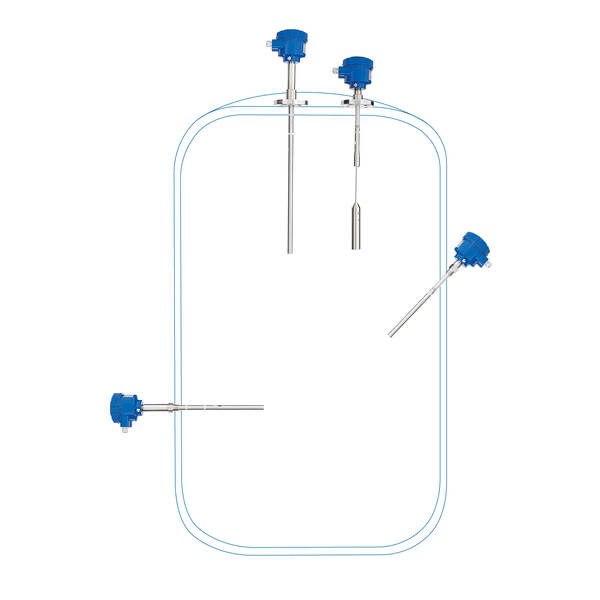

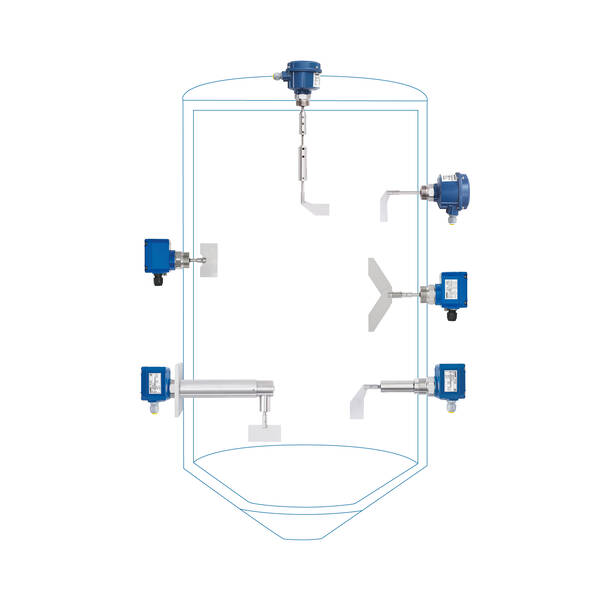

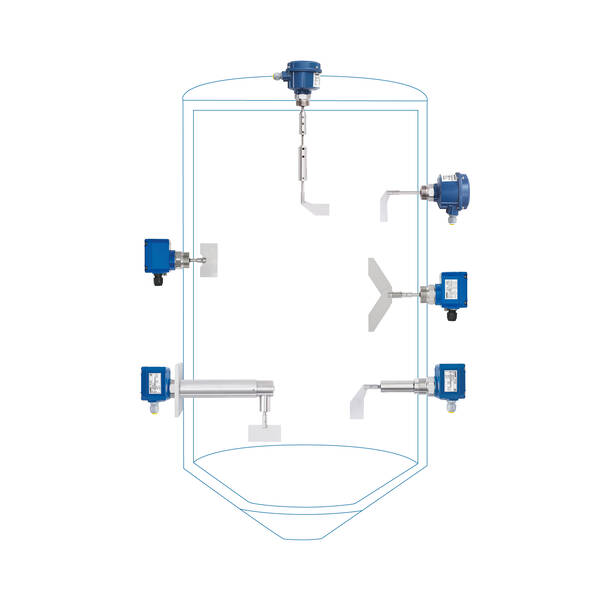

Capanivo® CN 7000 - Liquids - Capacitive Sensor for point level measurement

- Full, Demand, Empty Detector

- Level limit detection in liquids, slurries, foam,

interfaces and sol

Capanivo® CN 8000 - Liquids - Capacitive Sensor for point level measurement

- Rod or cable version

- Level limit detection in liquids, slurries, foam,

interfaces and solids.

RFnivo® RF 8000 - Liquids - Capacitive sensor for point level measurement.

- Wide range of applications in liquids

- Use up to 35bar and temperature up to 200°C

NivoCapa® NC 8000 - Liquids - Capacitive sensors are used for continuous level measurement in liquid and powder applications.

- Even at high process temperatures and pressures

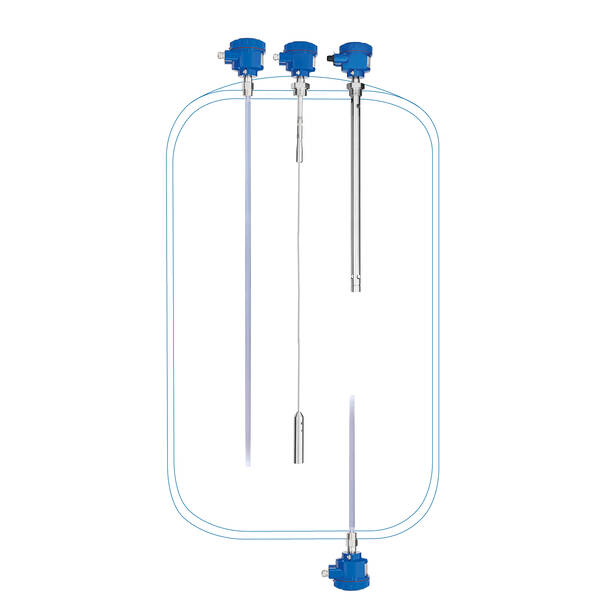

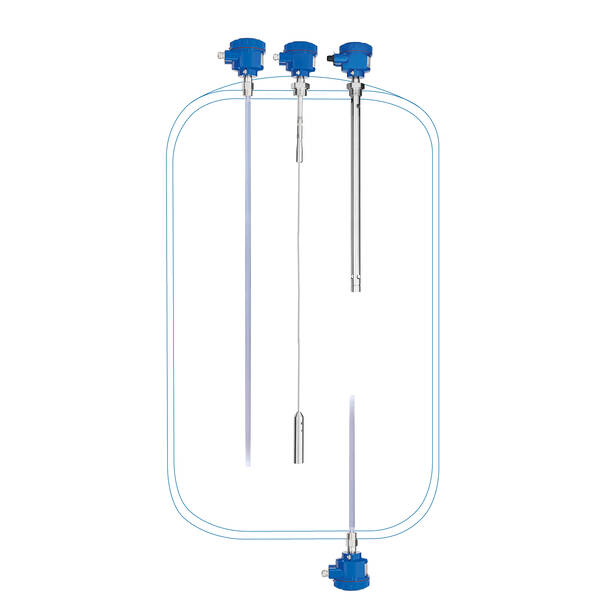

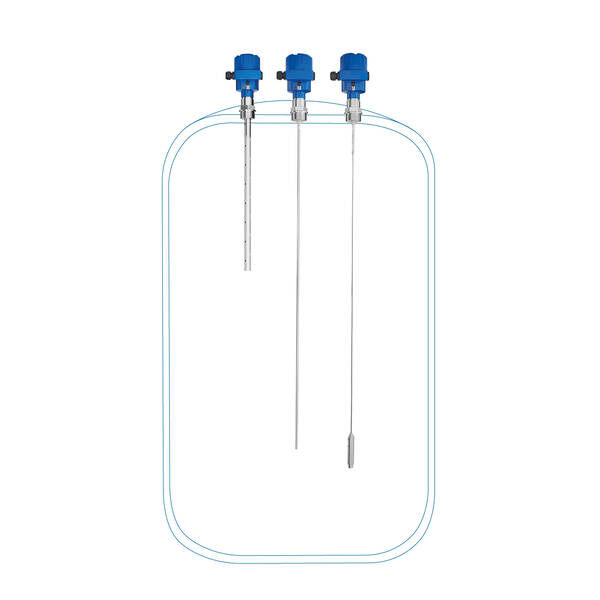

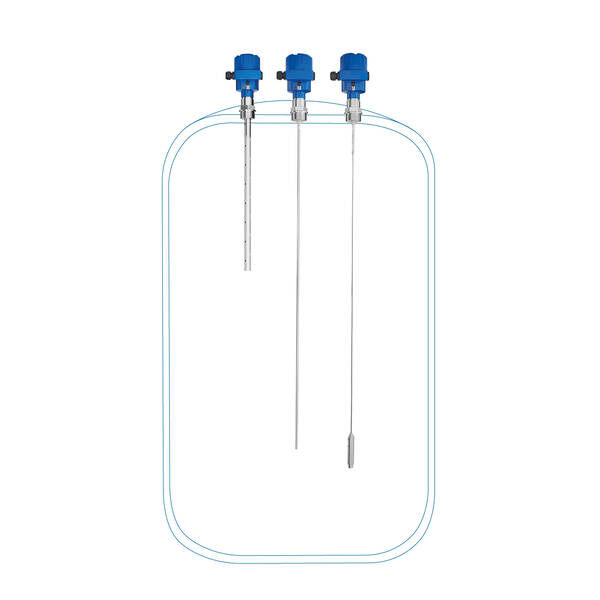

NivoGuide® NG 8000 - Liquids - TDR guided Radar for continous level measurement in liquids

- Temperature up to 200°C.

- Pressure up to 40bar.

- A variety of approvals available.

Rotonivo® - RN Serie - Solids - Rotary Paddle Level Switch

- reliable and maintenance-free limit switch for safe level detection in bulk solids

- for extreme process conditions

Vibranivo® - VN Serie - Vibration Level Limit Switch

- vibrating fork, with its robust stainless steel extension and high sensitivity, is widely used in storage process

Mononivo® MN 4000 - Solids - Vibration Level Limit Switch

-single-rod limit switches are suitable for many applications within the bulk material handling industry

RFnivo® RF 3000 - Solids - Capacitive sensor for point level measurement.

- Full, Demand, Empty Detector

- -40°C up to +240°C

- ATEX, IEC-Ex, FM, FMc, EHEDG

- Remoteversion

Capanivo® CN 4000 - Solids - Capacitive Sensor for point level measurement

- Full, Demand, Empty Detector

- Maintenance free, corrosion resistant

- Suitable for a wide range

NivoBob® NB 3000-4000 Solids - Electromechanical sensor for continuous level measurement

-Threaded or flange mounting.

-Measuring range up to 30m.

-Process temperatures up to 250

NivoRadar® - Sensoren - Continuous level measurement in storage silos or tanks

- small beam angle of 4°

- silos up to 100m

- all-rounder for most types of solids and liqui

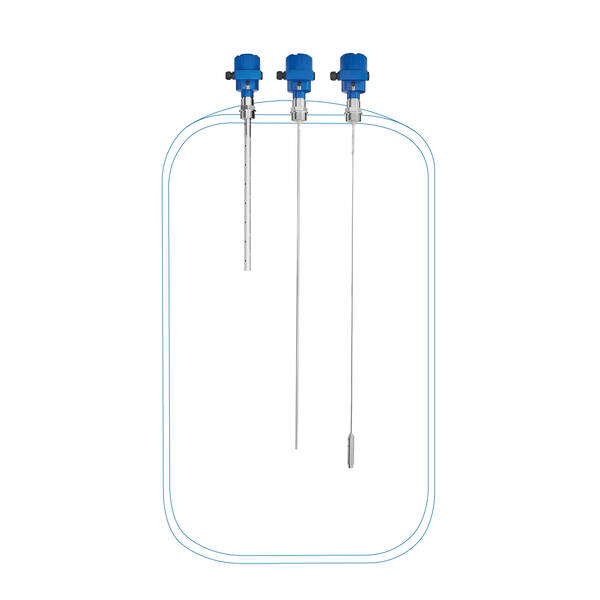

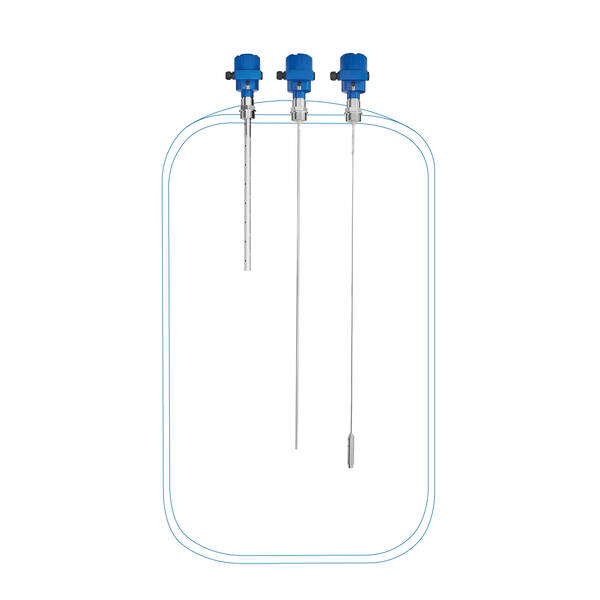

NivoGuide® NG 3000 - Solids - TDR guided radar sensor for continuous level measurement in solids

-High flexibility by shortenable probe

-up to 75m

-up to 200°C

- up to 40bar

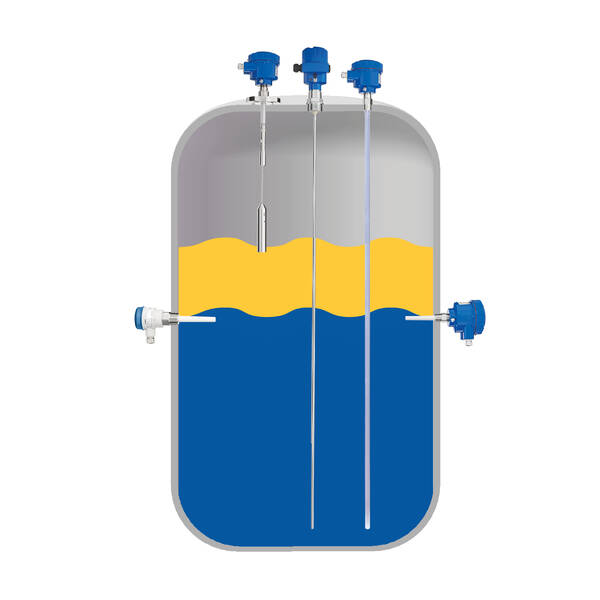

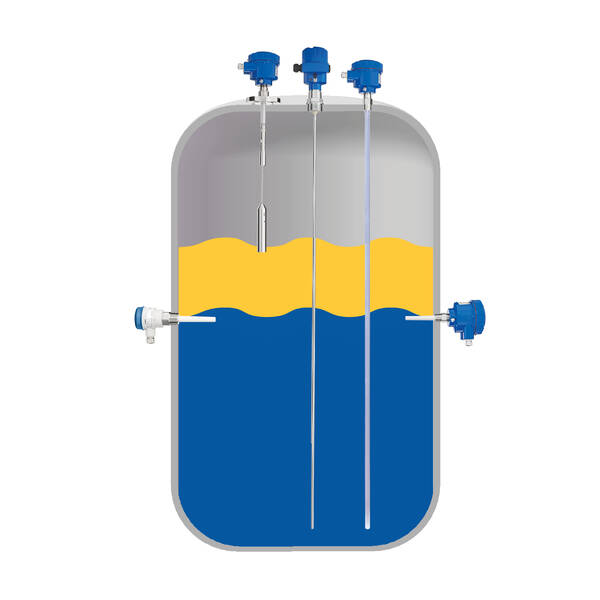

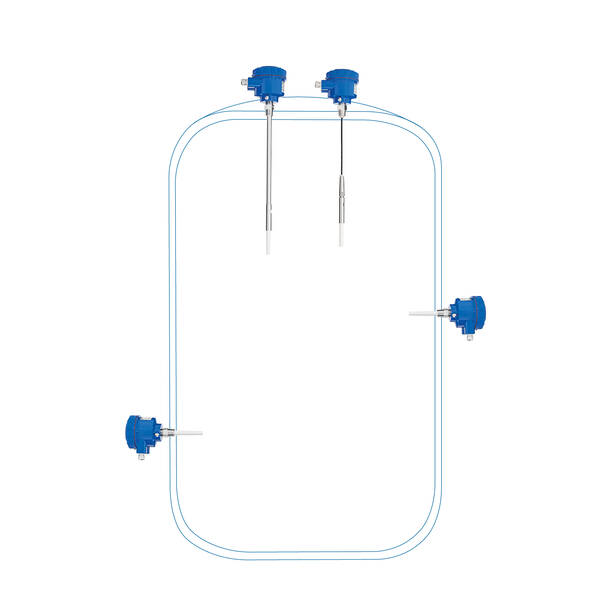

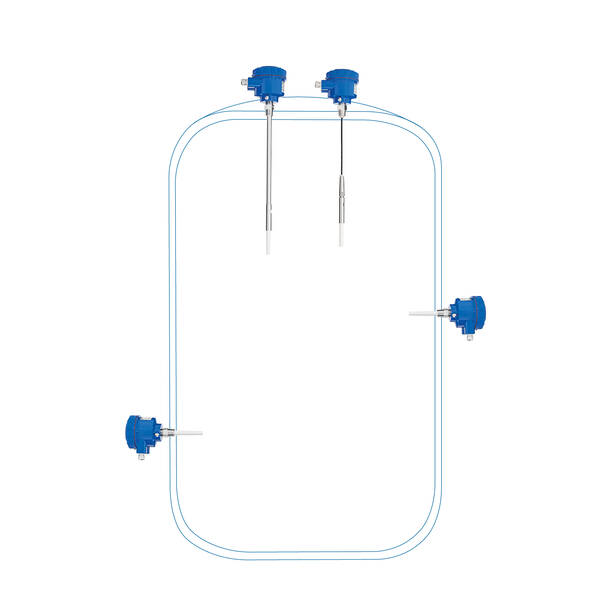

Trennschichtmessung-Interface - - The NivoBob® series NB 3300/3400 meet the needs of many interface measurements.

- Measurement of sludges and solids with Vibranivo® VN 1000/5000

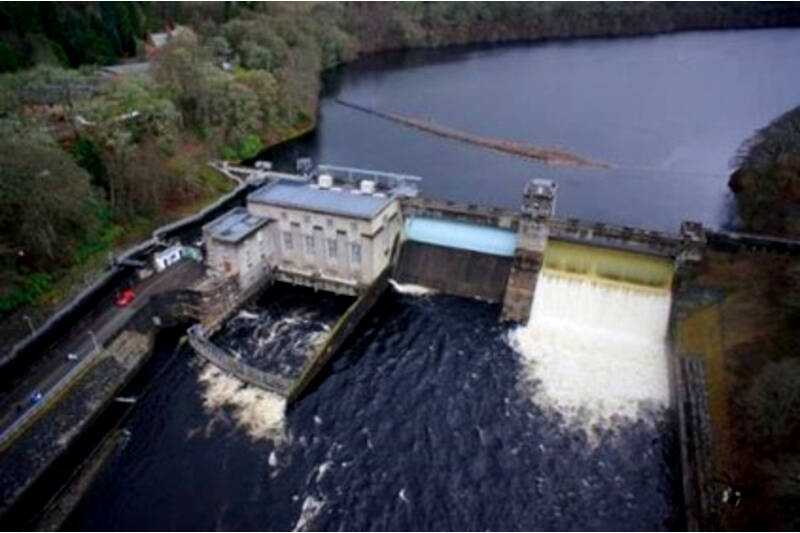

NivoTec® - Visualisierung - Complete systems for fill level and trend display, data storage and remote fill level information.

-adapted to the needs of our customers