Alpine Process Technology Summit: Spices, in Augsburg

Theoretical and practical knowledge about spice production. The conference in English, participation costs 295 euros per person. Whether turmeric or chilli, tea, coriander or caraway: every spice has its own specific properties and requirements. These should be taken into account in the production of high-quality food and in the development of efficient production processes. To gain a deeper understanding of these topics, Hosokawa Alpine AG is organising the Alpine Process Technology Summit | Spices at its headquarters in Augsburg on 16 and 17 April 2024.

The entire spectrum of spice processing

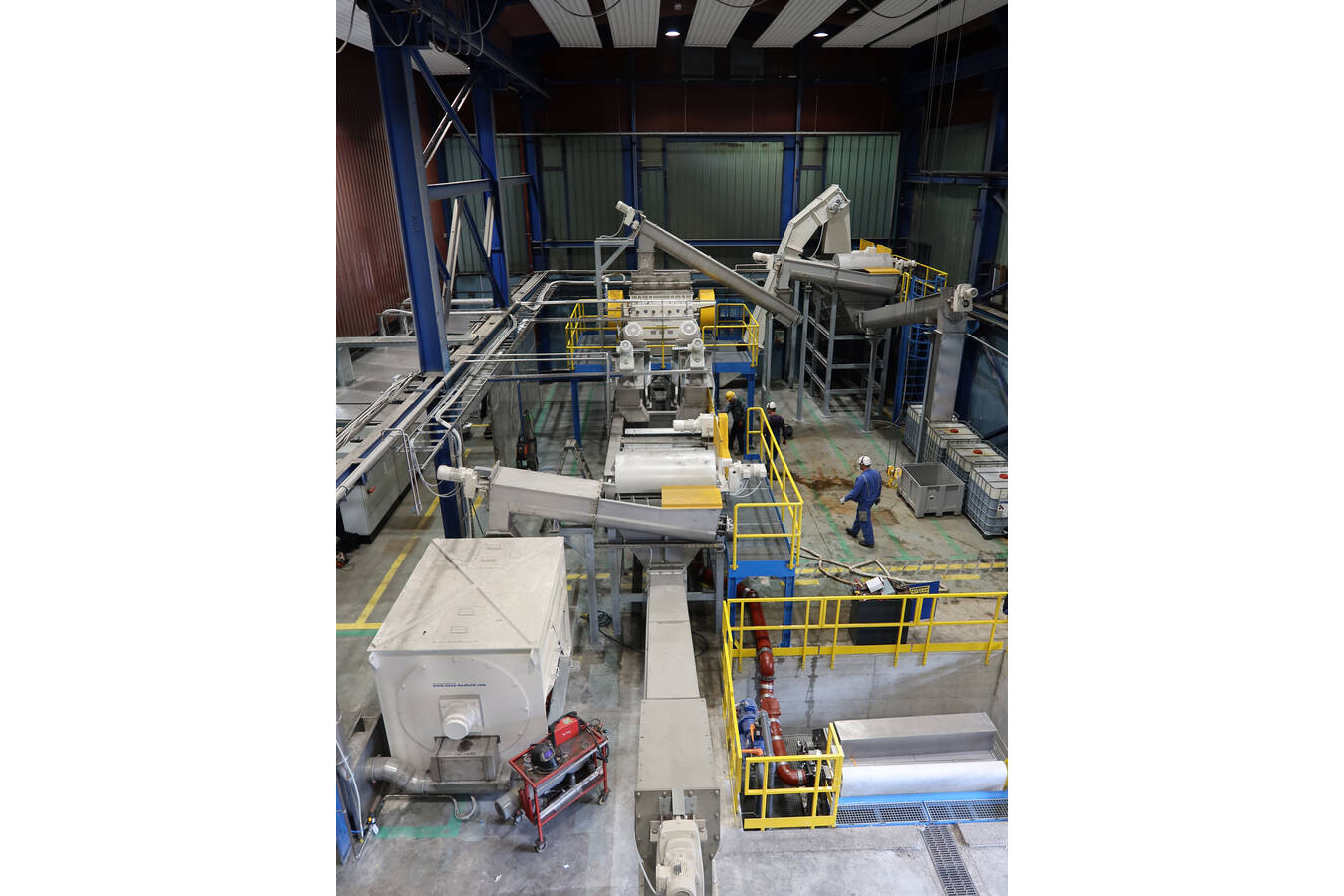

With the motto ”fit for future markets”, experts from Hosokawa Alpine, Behn + Bates, Hosokawa Micron B.V., Nexopart and Hosokawa Solids will share their in-depth expertise on spice processing with the participants. Topics range from cleaning, cutting, grinding and mixing to particle analysis, powder handling and packaging as well as after-sales service for existing plants. The technical presentations will go hand in hand with a practical session at Hosokawa Alpine’s test centre. ”The laboratory